-

Call

-

Email

orbitengineering01@gmail.com

-

Product Grid

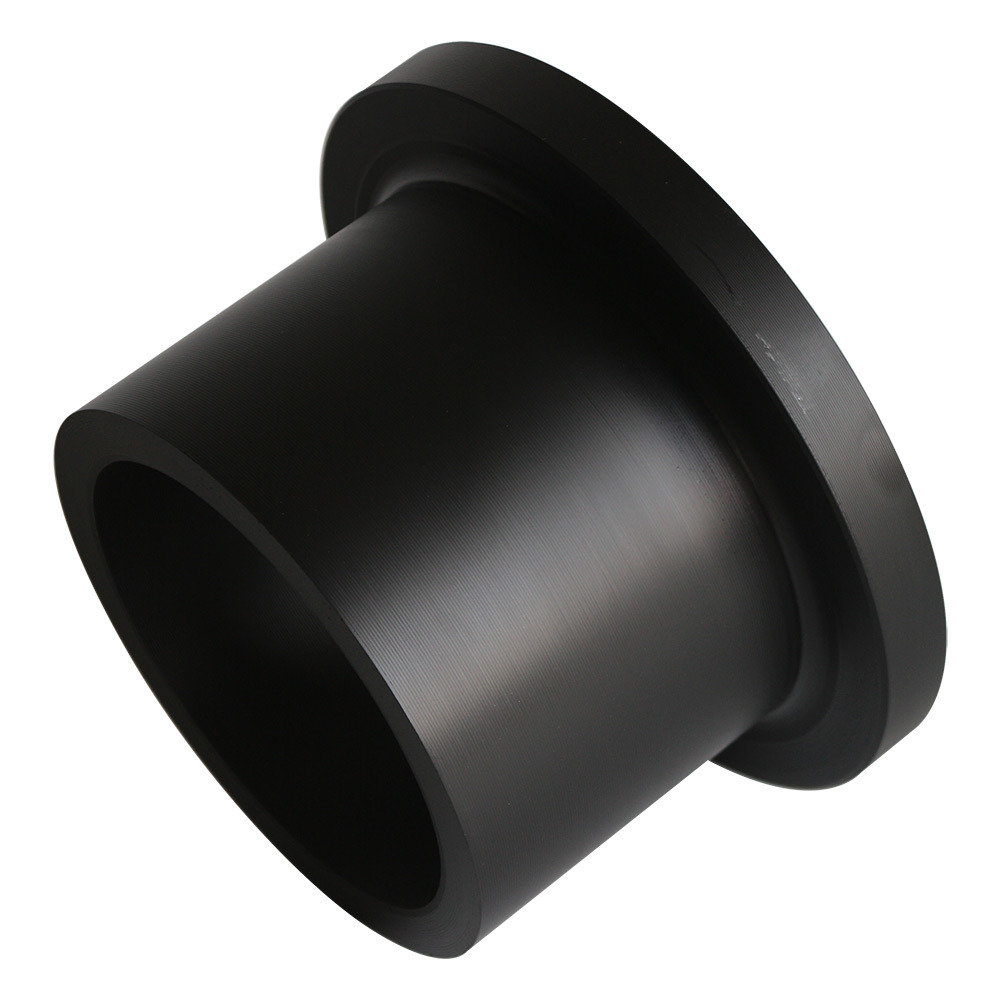

180 Deg Elbow

We, orbit engineering co., have an experience spanning for over three decades, producing and supplying best-in-class products, minimizing cost by getting manufacturing processes under one roof and delivering consignments on a daily basis only because of a diligent and dedicated team. We are manufacturers and suppliers, of Buttweld 180° Pipe Elbows, which are also known as ‘return elbows’, functioning to change the direction of the flow through a 180° angle. These SS 304 Buttweld 180 Degree Elbows are also available in customized sizes that give more elasticity and ease of handling in the process and control systems. Ancient to operate under a range of Buttweld 180 Degree Elbow, SS 180 deg. Elbow, 180-degree Buttweld Elbow extreme and actuating temperatures, our ANSI B16.9 180° Elbows are exported to many chemicals, engineering and industrial businesses.

Product Structure

Standard Specication For Buttweld 180 Deg. Pipe Elbow

Dimensions : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43

Size : Seamless Elbow ( 1/2″~24″), ERW / Welded / Fabricated Elbow (1/2″~48″)

Type : Seamless / ERW / Welded / Fabricated

Thickness : Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and

etc.

Form : Elbow, 180 Deg Elbow, Long Radius Elbow, Short Radius Elbow, LR Elbow, SR Elbow.

Material & Grades of Buttweld 180 Deg. Pipe Elbow :

Carbon Steel Buttweld 180° Pipe Elbow :

ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Low Temperature Carbon Steel 180° Pipe Elbow : ASTM A420 WPL3, A420 WPL6

Alloy Steel Buttweld 180° Pipe Elbow :

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

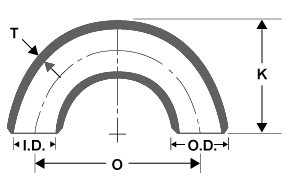

Technical Parameters

Carbon Steel Pipe Fitting – Long Radius 180 Return Bends

| Nominal | Outside | Inside | Wall | Center | Back To Face | Pipe | Weight |

| Pipe Size | Diameter | Diameter | Thickness | To Center | Schedule | Pounds | |

| 1/2 | 0.84 | 0.622 | 0.109 | 3 | 1.88 | 40 | 0.32 |

| 3/4 | 1.05 | 0.824 | 0.113 | 2.25 | 1.69 | 40 | 0.34 |

| 1 | 1.31 | 1.049 | 0.133 | 3 | 2.19 | 40 | 0.74 |

| 1 1/4 | 1.66 | 1.38 | 0.14 | 3.75 | 2.75 | 40 | 1.1 |

| 1 1/2 | 1.9 | 1.61 | 0.145 | 4.5 | 3.25 | 40 | 1.6 |

| 2 | 2.38 | 2.067 | 0.154 | 6 | 4.19 | 40 | 3.2 |

| 2 1/2 | 2.88 | 2.469 | 0.203 | 7.5 | 5.19 | 40 | 6.1 |

| 3 | 3.5 | 3.068 | 0.216 | 9 | 6.25 | 40 | 9.4 |

| 3 1/2 | 4 | 3.548 | 0.226 | 10.5 | 7.25 | 40 | 12.8 |

| 4 | 4.5 | 4.026 | 0.237 | 12 | 8.25 | 40 | 17.5 |

| 5 | 5.56 | 5.047 | 0.258 | 15 | 10.31 | 40 | 29.3 |

| 6 | 6.63 | 6.065 | 0.28 | 18 | 12.31 | 40 | 47 |

| 8 | 8.63 | 7.981 | 0.322 | 24 | 16.31 | 40 | 87 |

| 10 | 10.75 | 10.02 | 0.365 | 30 | 20.38 | 40 | 164 |

| 12 | 12.75 | 12 | 0.375 | 36 | 24.38 | * | 237 |

| 14 | 14 | 13.25 | 0.375 | 42 | 28 | 30 | 311 |

| 16 | 16 | 15.25 | 0.375 | 48 | 32 | 30 | 408 |

| 18 | 18 | 17.25 | 0.375 | 54 | 36 | * | 514 |

| 20 | 20 | 19.25 | 0.375 | 60 | 40 | 20 |

636

|

A

ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70