-

Call

-

Email

orbitengineering01@gmail.com

-

Product Grid

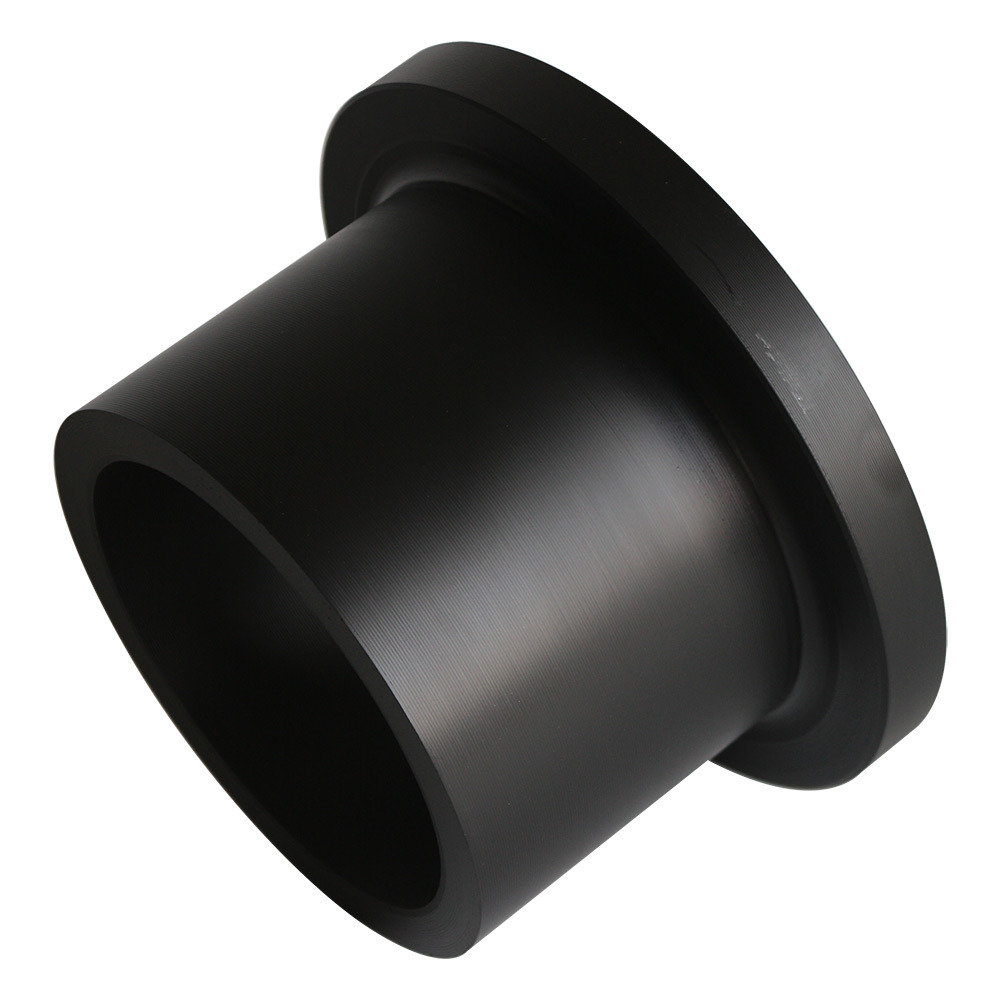

90 Deg Elbow

Buttweld 90° Pipe Elbows is one of the highly demandable products that are available in a variety of metals, materials, and sizes. The 90-degree pipe elbow not only success the industrial piping needs but they also perform as the reliable things that last for a long time.Moreover, the 90 degree bends over the quarter bend. The long radius and short radius elbows are used for high-temperature applications offering excellent performance in the long run. These elbows are lightweight and viable

economically.

Product Structure

Buttweld 90 Deg. Elbow Application

ASME B16.9 90 Degree Elbow are known to deliver exceptional performance and are generally developed for

meeting the demands. We oer a broad range of Buttweld 90 Degree Elbow through a network of

stock-keeping branches. These 90Deg. Buttweld Elbow is use in various industries like :

2019/7/2 Buttweld 90 Degree Elbow, SS 90 deg. Elbow, 90 degree Buttweld Elbow

https://www.neoimpex.com/asme-b16-9-buttweld-90-degree-pipe-elbow-manufacturer.html 4/8

Export Destinations For 90deg. Buttweld Pipe Elbow

Stainless Steel 90° Buttweld Elbow uses in Oil and Gas Pipeline

90° Buttweld Pipe Elbow uses in Chemical Industry

Alloy Steel 90° Elbow uses in Plumbing

Buttweld 90 Degree Pipe Elbow uses in Heating

90 Degree Buttweld Elbow uses in Water Supply Systems

ANSI B16.9 Buttweld 90° Pipe Elbow uses in Power Plant

90° Elbow uses in Paper & Pulp Industry

90° Degree Elbow uses in General Purpose Applications

Buttweld 90° Long Radius Elbow uses in Fabrication Industry

90° Buttweld Elbow uses in Food Processing Industry

Buttweld 90° Short Radius Elbow uses in Structural Pipe

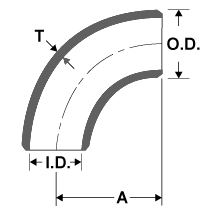

Technical Parameters

Carbon Steel Pipe Fitting – Long Radius Elbow 90

| Nominal | Outside | Inside | Wall | Center | Pipe | Weight |

| Pipe Size | Diameter | Diameter | Thickness | To End | Schedule | Pounds |

| 1/2 | 0.84 | 0.622 | 0.109 | 1.5 | 40 | 0.16 |

| 3/4 | 1.05 | 0.824 | 0.113 | 1.5 | 40 | 0.17 |

| 1 | 1.32 | 1.049 | 0.133 | 1.5 | 40 | 0.4 |

| 1 1/4 | 1.66 | 1.38 | 0.14 | 1.88 | 40 | 0.55 |

| 1 1/2 | 1.9 | 1.61 | 0.145 | 2.25 | 40 | 0.8 |

| 2 | 2.38 | 2.07 | 0.154 | 3 | 40 | 1.6 |

| 2 1/2 | 2.88 | 2.47 | 0.203 | 3.75 | 40 | 3.2 |

| 3 | 3.5 | 3.07 | 0.216 | 4.5 | 40 | 4.8 |

| 3 1/2 | 4 | 3.55 | 0.226 | 5.25 | 40 | 6.6 |

| 4 | 4.5 | 4.03 | 0.237 | 6 | 40 | 8.9 |

| 5 | 5.56 | 5.05 | 0.258 | 7.5 | 40 | 15.1 |

| 6 | 6.62 | 6.07 | 0.28 | 9 | 40 | 24 |

| 8 | 8.62 | 7.98 | 0.322 | 12 | 40 | 47.8 |

| 10 | 10.75 | 10.02 | 0.365 | 15 | 40 | 83.4 |

| 12 | 12.75 | 12 | 0.375 | 18 | * | 123 |

| 14 | 14 | 13.25 | 0.375 | 21 | 30 | 155 |

| 16 | 16 | 15.25 | 0.375 | 24 | 30 | 206 |

| 18 | 18 | 17.25 | 0.375 | 27 | * | 262 |

| 20 | 20 | 19.25 | 0.375 | 30 | 20 | 324 |

| 24 | 24 | 23.25 | 0.375 | 36 | 20 | 466 |

| 30 | 30 | 29.25 | 0.375 | 45 | * | 720 |

| 36 | 36 | 35.25 | 0.375 | 54 | * | 1,039 |

| 42 | 42 | 41.25 | 0.375 | 63 | * | 1,420 |

| 48 | 48 | 47.25 | 0.375 | 72 | * | 2,000 |

a

Carbon steel: ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.