-

Call

-

Email

orbitengineering01@gmail.com

-

Product Grid

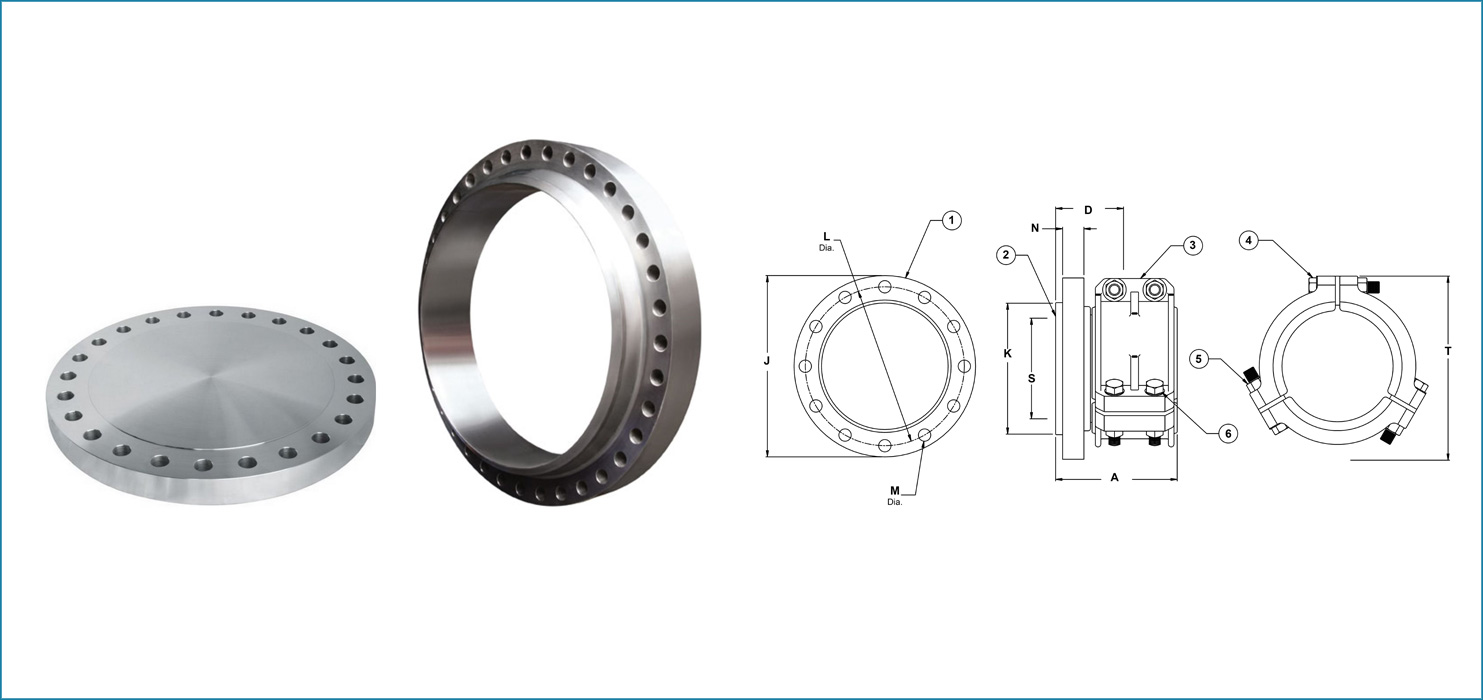

ANSI B16.47 Flanges

A relentless effort to keep on reinventing and innovating our products and services has made us a leading quality product dispensing company. Our customers are our priority. We are a manufacturer and supplier of ANSI B16.47 Flanges, which are large diameter flanges that are further classified into ANSI B16.47 Series A and ANSI B16.47 Series B flanges. ANSI B16.47 Series A flanges are upscale yet thicker, stronger and bulkier in their design than ANSI B16.47 Series B flanges, thus they perform well when equipped under massive pressure loads, with service applications in the load handling equipment and heavy-duty engineering services.

Description

Orbit Engineering co.

Orbit Engineering co.

|

Product Structure

Standard Specication For ANSI B16.47 Flanges

Dimensions : ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Size : 1/2″ (15 NB) to 48″ (1200NB)

Class : 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629,

DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673

BS : BS4504 , BS4504, BS1560, BS10

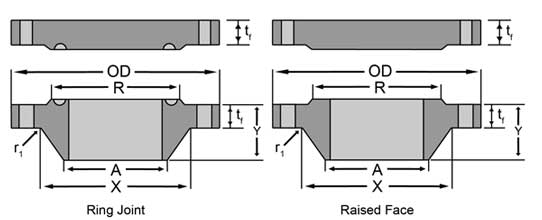

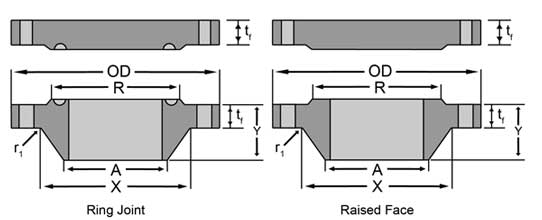

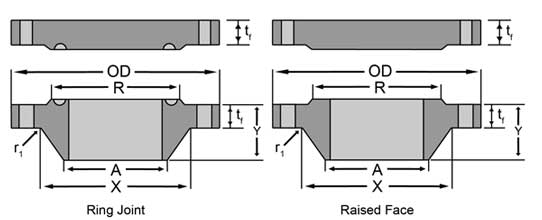

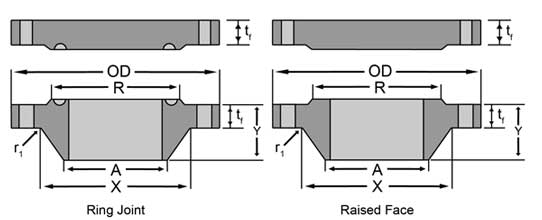

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Material & Grades of ANSI B16.47 Flanges :

Carbon Steel ANSI B16.47 Flanges :

ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706

Low Temperature Carbon Steel ANSI B16.47 Flanges : ASTM A350, LF2, LF3

Alloy Steel ANSI B16.47 Flanges :

ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

|

Technical Parameters

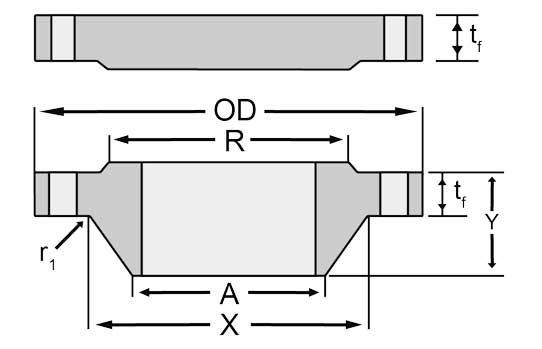

ASME B16.47 Series A Class 150 Flange Dimensions

| Nominal Size | Outside Diameter(OD) | Min. Thickness [Note1] – WNF (tf) |

Min. Thickness [Note1] – Blind (tf) |

Length Through Hub (Y) |

Hub Dia. Base [Note2] (X) |

Hub Dia. Top (A |

Raised Face Dia. (R) |

Drilling – Bolt Circle Dia | Drilling – No. of Bolt Holes | Drilling – Dia. of Bolt Hole | Dia. of Bolt | Min. Fillet Radius(r1) |

| 26 | 34.25 | 2.63 | 2.63 | 4.69 | 26.62 | 26 | 29.5 | 31.75 | 24 | 13⁄8 | 11⁄4 | 0.38 |

| 28 | 36.5 | 2.75 | 2.75 | 4.88 | 28.62 | 28 | 31.5 | 34 | 28 | 13⁄8 | 11⁄4 | 0.44 |

| 30 | 38.75 | 2.88 | 2.88 | 5.32 | 30.75 | 30 | 33.75 | 36 | 28 | 13⁄8 | 11⁄4 | 0.44 |

| 32 | 41.75 | 3.13 | 3.13 | 5.63 | 32.75 | 32 | 36 | 38.5 | 28 | 15⁄8 | 11⁄2 | 0.44 |

| 34 | 43.75 | 3.19 | 3.19 | 5.82 | 34.75 | 34 | 38 | 40.5 | 32 | 15⁄8 | 11⁄2 | 0.5 |

| 36 | 46 | 3.5 | 3.5 | 6.13 | 36.75 | 36 | 40.25 | 42.75 | 32 | 15⁄8 | 11⁄2 | 0.5 |

| 38 | 48.75 | 3.38 | 3.38 | 6.13 | 39 | 38 | 42.25 | 45.25 | 32 | 15⁄8 | 11⁄2 | 0.5 |

| 40 | 50.75 | 3.5 | 3.5 | 6.38 | 41 | 40 | 44.25 | 47.25 | 36 | 15⁄8 | 11⁄2 | 0.5 |

| 42 | 53 | 3.75 | 3.75 | 6.69 | 43 | 42 | 47 | 49.5 | 36 | 15⁄8 | 11⁄2 | 0.5 |

| 44 | 55.25 | 3.94 | 3.94 | 6.94 | 45 | 44 | 49 | 51.75 | 40 | 15⁄8 | 11⁄2 | 0.5 |

| 46 | 57.25 | 4 | 4 | 7.25 | 47.12 | 46 | 51 | 53.75 | 40 | 15⁄8 | 11⁄2 | 0.5 |

| 48 | 59.5 | 4.19 | 4.19 | 7.5 | 49.12 | 48 | 53.5 | 56 | 44 | 15⁄8 | 11⁄2 | 0.5 |

| 50 | 61.75 | 4.32 | 4.32 | 7.94 | 51.25 | 50 | 55.5 | 58.25 | 44 | 17⁄8 | 13⁄4 | 0.5 |

| 52 | 64 | 4.5 | 4.5 | 8.19 | 53.25 | 52 | 57.5 | 60.5 | 44 | 17⁄8 | 13⁄4 | 0.5 |

| 54 | 66.25 | 4.69 | 4.69 | 8.44 | 55.25 | 54 | 59.5 | 62.75 | 44 | 17⁄8 | 13⁄4 | 0.5 |

| 56 | 68.75 | 4.82 | 4.82 | 8.94 | 57.38 | 56 | 62 | 65 | 48 | 17⁄8 | 13⁄4 | 0.5 |

| 58 | 71 | 5 | 5 | 9.19 | 59.38 | 58 | 64 | 67.25 | 48 | 17⁄8 | 13⁄4 | 0.5 |

| 60 | 73 | 5.13 | 5.13 | 9.38 | 61.38 | 60 | 66 | 69.25 | 52 | 17⁄8 | 13⁄4 | 0.5 |

Dimensions are in inches.

1) The minimum flange thickness does not include the raised face thickness

2) This dimension is for the large end of hub, which may be straight or tapered.

3) Weldneck Bore/ID is to be specified by the purchaser

4) For other details and tolerances see specification.

ANSI/ASME B16.47 Series A Class 300 Flange Dimensions

| Nominal Size | Outside Diameter(OD) | Min. Thickness [Note1] – WNF (tf) |

Min. Thickness [Note1] – Blind (tf) |

Length Through Hub (Y) |

Hub Dia. Base [Note2] (X) |

Hub Dia. Top (A |

Raised Face Dia. (R) |

Drilling – Bolt Circle Dia | Drilling – No. of Bolt Holes | Drilling – Dia. of Bolt Hole | Dia. of Bolt | Min. Fillet Radius(r1) |

| 26 | 38.25 | 3.07 | 3.25 | 7.19 | 28.38 | 26 | 29.5 | 34.5 | 28 | 13/4 | 15/8 | 0.38 |

| 28 | 40.75 | 3.32 | 3.5 | 7.69 | 30.5 | 28 | 31.5 | 37 | 28 | 13/4 | 15/8 | 0.44 |

| 30 | 43 | 3.57 | 3.69 | 8.19 | 32.56 | 30 | 33.75 | 39.25 | 28 | 17/8 | 13/4 | 0.44 |

| 32 | 45.25 | 3.82 | 3.88 | 8.69 | 34.69 | 32 | 36 | 41.5 | 28 | 2 | 17/8 | 0.44 |

| 34 | 47.5 | 3.94 | 4.07 | 9.07 | 36.88 | 34 | 38 | 43.5 | 28 | 2 | 17/8 | 0.5 |

| 36 | 50 | 4.07 | 4.32 | 9.44 | 39 | 36 | 40.25 | 46 | 32 | 21/8 | 2 | 0.5 |

| 38 | 46 | 4.19 | 4.19 | 7.06 | 39.12 | 38 | 40.5 | 43 | 32 | 15/8 | 11/2 | 0.5 |

| 40 | 48.75 | 4.44 | 4.44 | 7.56 | 41.25 | 40 | 42.75 | 45.5 | 32 | 13/4 | 15/8 | 0.5 |

| 42 | 50.75 | 4.63 | 4.63 | 7.82 | 43.25 | 42 | 44.75 | 47.5 | 32 | 13/4 | 15/8 | 0.5 |

| 44 | 53.25 | 4.82 | 4.82 | 8.06 | 45.25 | 44 | 47 | 49.75 | 32 | 17/8 | 13/4 | 0.5 |

| 46 | 55.75 | 5 | 5 | 8.44 | 47.38 | 46 | 49 | 52 | 28 | 2 | 17/8 | 0.5 |

| 48 | 57.75 | 5.19 | 5.19 | 8.75 | 49.38 | 48 | 51.25 | 54 | 32 | 2 | 17/8 | 0.5 |

| 50 | 60.25 | 5.44 | 5.44 | 9.07 | 51.38 | 50 | 53.5 | 56.25 | 32 | 21/8 | 2 | 0.5 |

| 52 | 62.25 | 5.63 | 5.63 | 9.32 | 53.38 | 52 | 55.5 | 58.25 | 32 | 21/8 | 2 | 0.5 |

| 54 | 65.25 | 5.94 | 5.94 | 9.88 | 55.5 | 54 | 57.75 | 61 | 28 | 23/8 | 21/4 | 0.5 |

| 56 | 67.25 | 6 | 6 | 10.19 | 57.62 | 56 | 59.75 | 63 | 28 | 23/8 | 21/4 | 0.5 |

| 58 | 69.25 | 6.19 | 6.19 | 10.44 | 59.62 | 58 | 62 | 65 | 32 | 23/8 | 21/4 | 0.5 |

| 60 | 71.25 | 6.38 | 6.38 | 10.69 | 61.62 | 60 | 64 | 67 | 32 | 23/8 | 21/4 | 0.5 |

ANSI B16.47 Series A Class 400 Flange Dimensions

| Nominal Size | Outside Diameter(OD) | Min. Thickness [Note1] – WNF (tf) |

Min. Thickness [Note1] – Blind (tf) |

Length Through Hub (Y) |

Hub Dia. Base [Note2] (X) |

Hub Dia. Top (A |

Raised Face Dia. (R) |

Drilling – Bolt Circle Dia | Drilling – No. of Bolt Holes | Drilling – Dia. of Bolt Hole | Dia. of Bolt | Min. Fillet Radius(r1) |

| 26 | 38.25 | 3.5 | 3.88 | 7.62 | 28.62 | 26 | 29.5 | 34.5 | 28 | 17/8 | 13/4 | 0.44 |

| 28 | 40.75 | 3.75 | 4.12 | 8.12 | 30.81 | 28 | 31.5 | 37 | 28 | 2 | 17/8 | 0.5 |

| 30 | 43 | 4 | 4.38 | 8.62 | 32.94 | 30 | 33.75 | 39.25 | 28 | 21/8 | 2 | 0.5 |

| 32 | 45.25 | 4.25 | 4.56 | 9.12 | 35 | 32 | 36 | 41.5 | 28 | 21/8 | 2 | 0.5 |

| 34 | 47.5 | 4.38 | 4.81 | 9.5 | 37.19 | 34 | 38 | 43.5 | 28 | 21/8 | 2 | 0.56 |

| 36 | 50 | 4.5 | 5.06 | 9.88 | 39.38 | 36 | 40.25 | 46 | 32 | 21/8 | 2 | 0.56 |

| 38 | 47.5 | 4.88 | 4.88 | 8.12 | 39.5 | 38 | 40.75 | 44 | 32 | 17/8 | 13/4 | 0.56 |

| 40 | 50 | 5.12 | 5.12 | 8.5 | 41.5 | 40 | 43 | 46.25 | 32 | 2 | 17/8 | 0.56 |

| 42 | 52 | 5.25 | 5.25 | 8.81 | 43.62 | 42 | 45 | 48.25 | 32 | 2 | 17/8 | 0.56 |

| 44 | 54.5 | 5.5 | 5.5 | 9.18 | 45.62 | 44 | 47.25 | 50.5 | 32 | 21/8 | 2 | 0.56 |

| 46 | 56.75 | 5.75 | 5.75 | 9.62 | 47.75 | 46 | 49.5 | 52.75 | 36 | 21/8 | 2 | 0.56 |

| 48 | 59.5 | 6 | 6 | 10.12 | 49.88 | 48 | 51.5 | 55.25 | 28 | 23/8 | 21/4 | 0.56 |

| 50 | 61.75 | 6.19 | 6.25 | 10.56 | 52 | 50 | 53.62 | 57.5 | 32 | 23/8 | 21/4 | 0.56 |

| 52 | 63.75 | 6.38 | 6.44 | 10.88 | 54 | 52 | 55.62 | 59.5 | 32 | 23/8 | 21/4 | 0.56 |

| 54 | 67 | 6.69 | 6.75 | 11.38 | 56.12 | 54 | 57.88 | 62.25 | 28 | 25/8 | 21/2 | 0.56 |

| 56 | 69 | 6.88 | 6.94 | 11.75 | 58.25 | 56 | 60.12 | 64.25 | 32 | 25/8 | 21/2 | 0.56 |

| 58 | 71 | 7 | 7.12 | 12.06 | 60.25 | 58 | 62.12 | 66.25 | 32 | 25/8 | 21/2 | 0.56 |

| 60 | 74.25 | 7.31 | 7.44 | 12.56 | 62.38 | 60 | 64.38 | 69 | 32 | 27/8 | 23/4 | 0.56 |

ANSI B16.47 Series A Class 600 Flange Dimension

| Nominal Size | Outside Diameter(OD) | Min. Thickness [Note1] – WNF (tf) |

Min. Thickness [Note1] – Blind (tf) |

Length Through Hub (Y) |

Hub Dia. Base [Note2] (X) |

Hub Dia. Top (A |

Raised Face Dia. (R) |

Drilling – Bolt Circle Dia | Drilling – No. of Bolt Holes | Drilling – Dia. of Bolt Hole | Dia. of Bolt | Min. Fillet Radius(r1) |

| 26 | 40 | 4.25 | 4.94 | 8.75 | 29.44 | 26 | 29.5 | 36 | 28 | 2 | 17/8 | 0.5 |

| 28 | 42.25 | 4.38 | 5.19 | 9.25 | 31.62 | 28 | 31.5 | 38 | 28 | 21/8 | 2 | 0.5 |

| 30 | 44.5 | 4.5 | 5.5 | 9.75 | 33.94 | 30 | 33.75 | 40.25 | 28 | 21/8 | 2 | 0.5 |

| 32 | 47 | 4.62 | 5.81 | 10.25 | 36.12 | 32 | 36 | 42.5 | 28 | 23/8 | 21/4 | 0.5 |

| 34 | 49 | 4.75 | 6.06 | 10.62 | 38.31 | 34 | 38 | 44.5 | 28 | 23/8 | 21/4 | 0.56 |

| 36 | 51.75 | 4.88 | 6.38 | 11.12 | 40.62 | 36 | 40.25 | 47 | 28 | 25/8 | 21/2 | 0.56 |

| 38 | 50 | 6 | 6.12 | 10 | 40.25 | 38 | 41.5 | 45.75 | 28 | 23/8 | 21/4 | 0.56 |

| 40 | 52 | 6.25 | 6.38 | 10.38 | 42.25 | 40 | 43.75 | 47.75 | 32 | 23/8 | 21/4 | 0.56 |

| 42 | 55.25 | 6.62 | 6.75 | 11 | 44.38 | 42 | 46 | 50.5 | 28 | 25/8 | 21/2 | 0.56 |

| 44 | 57.25 | 6.81 | 7 | 11.38 | 46.5 | 44 | 48.25 | 52.5 | 32 | 25/8 | 21/2 | 0.56 |

| 46 | 59.5 | 7.06 | 7.31 | 11.81 | 48.62 | 46 | 50.25 | 54.75 | 32 | 25/8 | 21/2 | 0.56 |

| 48 | 62.75 | 7.44 | 7.69 | 12.44 | 50.75 | 48 | 52.5 | 57.5 | 32 | 27/8 | 23/4 | 0.56 |

| 50 | 65.75 | 7.75 | 8 | 12.94 | 52.88 | 50 | 54.5 | 60 | 28 | 31/8 | 3 | 0.56 |

| 52 | 67.75 | 8 | 8.25 | 13.25 | 54.88 | 52 | 56.5 | 62 | 32 | 31/8 | 3 | 0.56 |

| 54 | 70 | 8.25 | 8.56 | 13.75 | 57 | 54 | 58.75 | 64.25 | 32 | 31/8 | 3 | 0.56 |

| 56 | 73 | 8.56 | 8.88 | 14.25 | 59.12 | 56 | 60.75 | 66.75 | 32 | 33/8 | 31/4 | 0.62 |

| 58 | 75 | 8.75 | 9.12 | 14.56 | 61.12 | 58 | 63 | 68.75 | 32 | 33/8 | 31/4 | 0.62 |

| 60 | 78.5 | 9.19 | 9.56 | 15.31 | 63.38 | 60 | 65.25 | 71.75 | 28 | 35/8 | 31/2 | 0.69 |

ASME B16.47 Series A Class 900 Flange Dimensions

| Nominal Size | Outside Diameter(OD) | Min. Thickness [Note1] – WNF (tf) |

Min. Thickness [Note1] – Blind (tf) |

Length Through Hub (Y) |

Hub Dia. Base [Note2] (X) |

Hub Dia. Top (A |

Raised Face Dia. (R) |

Drilling – Bolt Circle Dia | Drilling – No. of Bolt Holes | Drilling – Dia. of Bolt Hole | Dia. of Bolt | Min. Fillet Radius(r1) |

| 26 | 42.75 | 5.5 | 6.31 | 11.25 | 30.5 | 26 | 29.5 | 37.5 | 20 | 27/8 | 23/4 | 0.44 |

| 28 | 46 | 5.62 | 6.75 | 11.75 | 32.75 | 28 | 31.5 | 40.25 | 20 | 31/8 | 3 | 0.5 |

| 30 | 48.5 | 5.88 | 7.18 | 12.25 | 35 | 30 | 33.75 | 42.75 | 20 | 31/8 | 3 | 0.5 |

| 32 | 51.75 | 6.25 | 7.62 | 13 | 37.25 | 32 | 36 | 45.5 | 20 | 33/8 | 31/4 | 0.5 |

| 34 | 55 | 6.5 | 8.06 | 13.75 | 39.62 | 34 | 38 | 48.25 | 20 | 35/8 | 31/2 | 0.56 |

| 36 | 57.5 | 6.75 | 8.44 | 14.25 | 41.88 | 36 | 40.25 | 50.75 | 20 | 35/8 | 31/2 | 0.56 |

| 38 | 57.5 | 7.5 | 8.5 | 13.88 | 42.25 | 38 | 43.25 | 50.75 | 20 | 35/8 | 31/2 | 0.75 |

| 40 | 59.5 | 7.75 | 8.81 | 14.31 | 44.38 | 40 | 45.75 | 52.75 | 24 | 35/8 | 31/2 | 0.81 |

| 42 | 61.5 | 8.12 | 9.12 | 14.62 | 46.31 | 42 | 47.75 | 54.75 | 24 | 35/8 | 31/2 | 0.81 |

| 44 | 64.88 | 8.44 | 9.56 | 15.38 | 48.62 | 44 | 50 | 57.62 | 24 | 37/8 | 33/4 | 0.88 |

| 46 | 68.25 | 8.88 | 10.06 | 16.18 | 50.88 | 46 | 52.5 | 60.5 | 24 | 41/8 | 4 | 0.88 |

| 48 | 70.25 | 9.19 | 10.38 | 16.5 | 52.88 | 48 | 54.5 | 62.5 | 24 | 41/8 | 4 | 0.94 |

|

Application

ANSI B16.5 ANSI B16.47 Flanges Application

ANSI B16.47 ANSI B16.47 Flanges are known to deliver exceptional performance and are generally developed for

meeting the demands. We offer a broad range of ANSI B16.47 Flanges through a network of stock keeping branches. These ANSI B16.47 Flange is use in various industries like :

Export Destinations For ANSI B16.47 Flanges

Stainless Steel ANSI B16.47 Flanges uses in Oil and Gas Pipeline

ANSI B16.47 Flanges uses in Chemical Industry

Alloy Steel ANSI B16.47 Flanges uses in Plumbing

ANSI B16.47 Flanges uses in Heating

ANSI B16.47 Pipe Flanges uses in Water Supply Systems

ANSI B16.5 ANSI B16.47 ANSI B16.47 Flanges uses in Power Plant

ANSI B16.47 Flanges uses in Paper & Pulp Industry

ANSI B16.47 Flange uses in General Purpose Applications

Steel ANSI B16.47 Flanges uses in Fabrication Industry

ANSI B16.47 Flange uses in Food Processing Industry

ANSI B16.47 Flanges uses in Structural Pipe

|

Related products

ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706