-

Call

-

Email

orbitengineering01@gmail.com

-

Product Grid

B16.5 Class 300 – NPS 1/2-24

description

Description

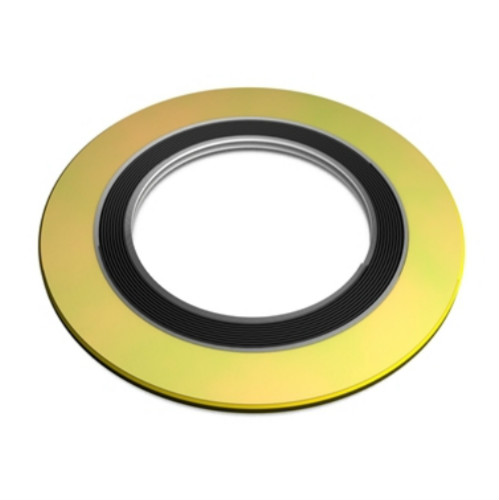

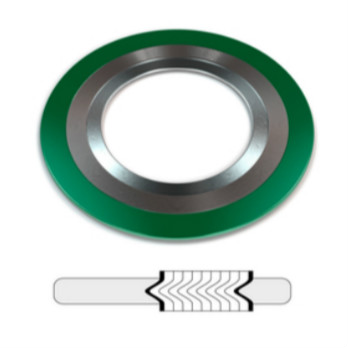

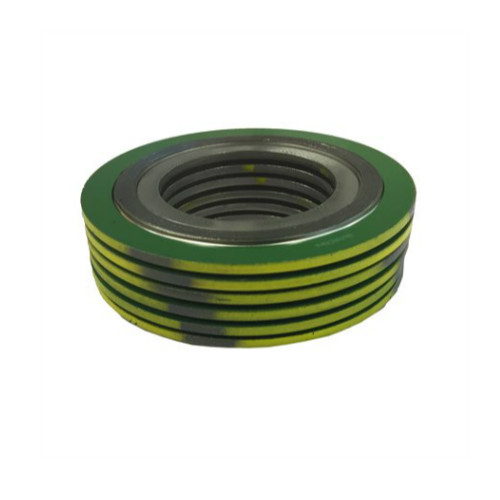

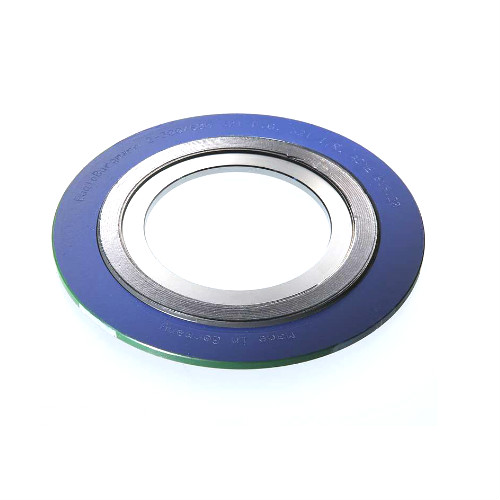

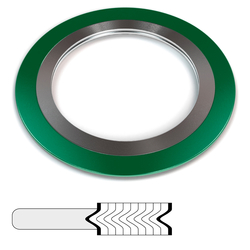

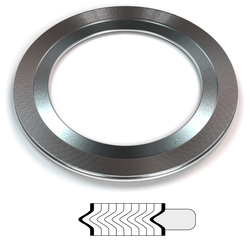

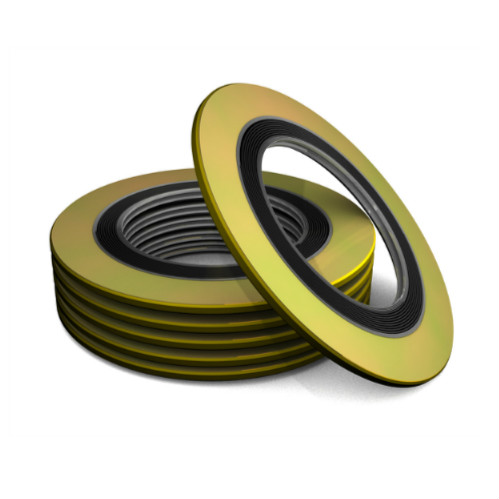

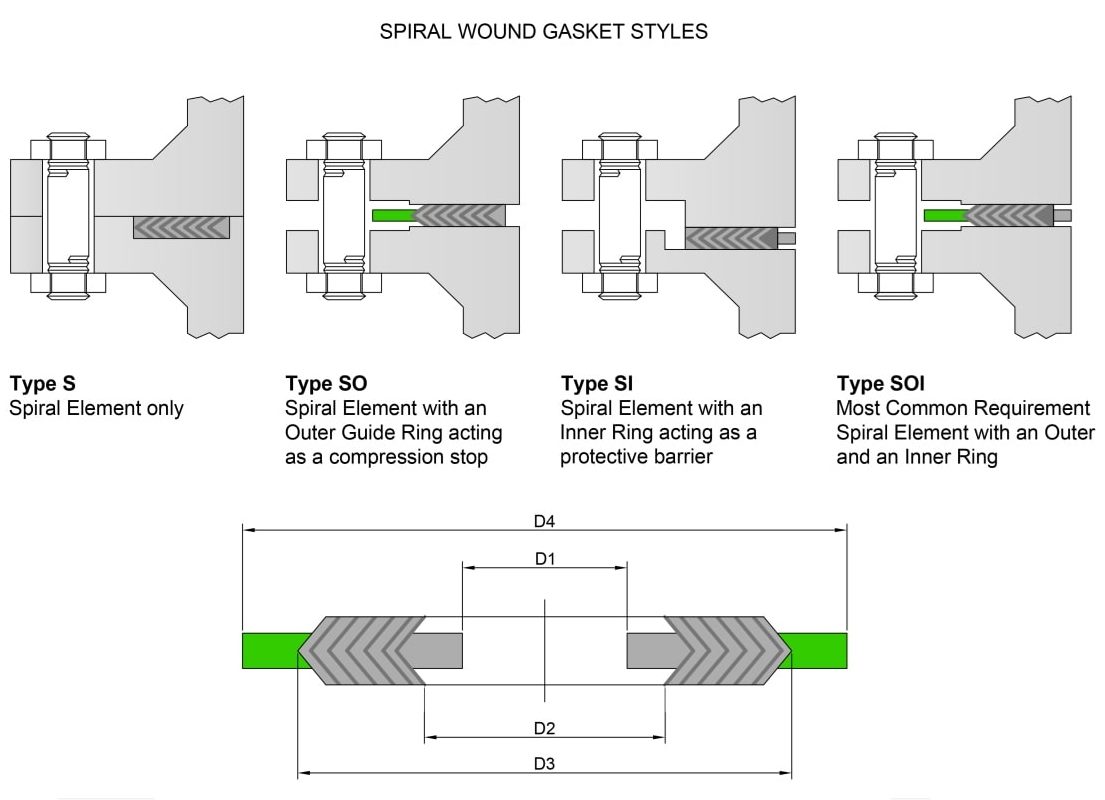

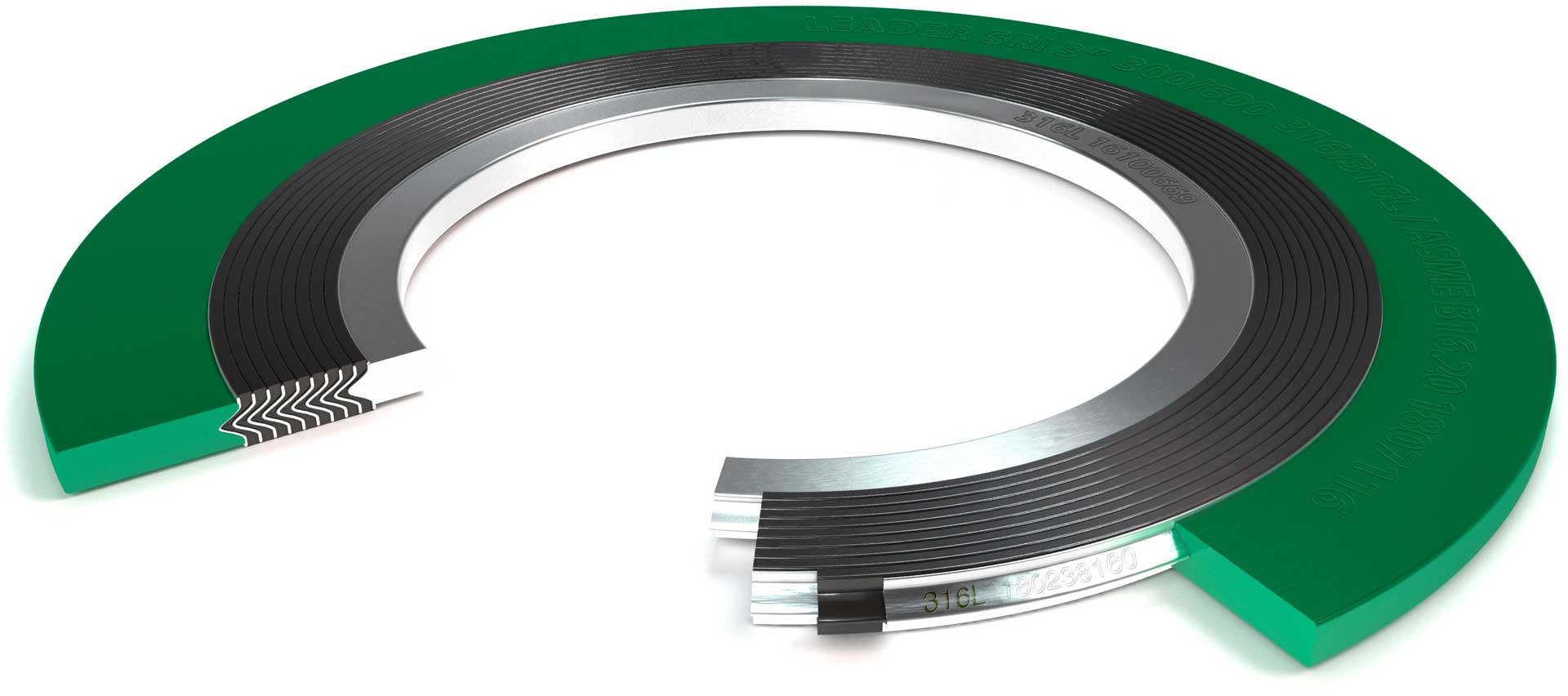

The main characteristic of the Spiral Wound Gasket is the sealing element itself which is manufactured by spirally winding a ‘V’ shaped metallic strip and incorporating a soft filler, generally Graphite, PTFE or specially developed High-Temperature material and it is this that maintains an effective seal at varying temperatures and pressures.

The main characteristic of the Spiral Wound Gasket is the sealing element itself which is manufactured by spirally winding a ‘V’ shaped metallic strip and incorporating a soft filler, generally Graphite, PTFE or specially developed High-Temperature material and it is this that maintains an effective seal at varying temperatures and pressures.

The Spiral Wound Gasket configuration can also include an outer and inner ring. The outer ring acts as a locator within the bolt circle and also as a compression stop supporting the sealing element and resisting ‘blow-out’ by preventing over-compression whilst the inner ring acts as a heat shield and corrosion barrier to protect the actual spiral element from media attack.

Material construction generally depends on the application conditions, predominantly media, temperature and pressure values, the most common construction is 316 Stainless Steel Winding and Inner Ring, a Carbon Steel Outer Ring and Graphite Filler Material.

|

Product Structure

Spiral wound gaskets are used in Refinery, Petrochemical, Chemical, Steam lines and Process Industries, where they have many advantages over older types of gaskets.

FLANGE STANDARDS

FLANGE STANDARDS SOR, SIO, SIOH, SIR type spiral wound gaskets can be manufactured in accordance with all relevant gasket standards and specifications to suit the following

| ASME/ANSIB16.5 | MSS SP44 (ASME B16.47 SERIES A) (AWWA) |

| BS 1560, BS10, BS4504 | DIN FLANGES, JIS FLANGES |

| API 605 (ASME B16.47 SERIES B) | FRENCH NF STANDARD |

COMMON FILLERS USED

| FILLERS MATERIALS | MAX. WORKING TEMPERATURE |

|---|---|

| Graphite Mica | 350 F (Temperature) |

| Graphite 99.8% purity | 1200 C |

| Non-asbestos | 550 C |

| PTFE | 250 C |

| Ceramic | 1000 C |

WINDING MATERIAL:

| SS304 | 650 Deg C |

| SS316 | 800 Deg C |

| SS347 | 870 Deg C |

| SS321 | 870 Deg C |

| Monal400 | 800 Deg C |

| Nickel 200 | 600 Deg C |

| Titanium | 540 Deg C |

| Iconel600 | 1000 Deg C |

| Inconel625 | 1000 Deg C |

| Incoloy825 | 1000 Deg C |

INNER AND OUTER RING

Carbon Steel, Stainless Steel 304,304L, 316,316L,316Ti,321,347, MONEL® 400,Inconel® 600,625,800, Incoloy® 800, 825, Nickel 200, Titanium, Hastelloy, Copper.

SPIRAL WOUND GASKET SIZES

Size & Shape as per Prevailing International standards or Customer needs can be produce

|

Technical Parameters

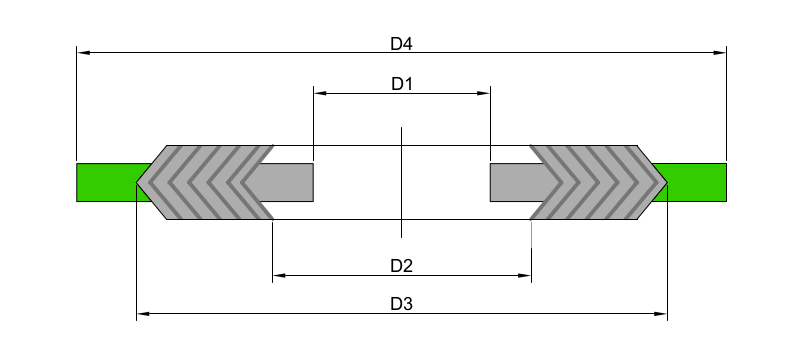

Spiral wound Gasket Dimensions: ASME B16.20: For Flanges to B16.5 CLASS 300 LB

| NPS | Inner Ring | Sealing | Element | Outer Ring |

|---|---|---|---|---|

| Inside Dia (d1) | Inside Dia (d2) | Outside Dia (d3) | Outside Dia (d4) | |

| ½ | 14.2 | 19.1 | 31.8 | 54.1 |

| ¾ | 20.6 | 25.4 | 39.6 | 66.8 |

| 1 | 26.9 | 31.8 | 47.8 | 73.2 |

| 1 ¼ | 38.1 | 47.8 | 60.5 | 82.6 |

| 1 ½ | 44.5 | 54.1 | 69.9 | 95.3 |

| 2 | 55.6 | 69.9 | 85.9 | 111.3 |

| 2 | ½ 66.5 | 82.6 | 98.6 | 130.3 |

| 3 | 81.0 | 101.6 | 120.7 | 149.4 |

| 4 | 106.4 | 127.0 | 149.4 | 181.1 |

| 5 | 131.8 | 155.7 | 177.8 | 215.9 |

| 6 | 157.2 | 182.6 | 209.6 | 251.0 |

| 8 | 215.9 | 233.4 | 263.7 | 308.1 |

| 10 | 268.2 | 287.3 | 317.5 | 362.0 |

| 12 | 317.5 | 339.9 | 374.7 | 422.4 |

| 14 | 349.3 | 371.6 | 406.4 | 485.9 |

| 16 | 400.1 | 422.4 | 463.6 | 539.8 |

| 18 | 449.3 | 474.7 | 527.1 | 596.9 |

| 20 | 500.1 | 525.6 | 577.9 | 654.1 |

| 24 | 603.3 | 628.7 | 685.8 | 774.7 |

|

Related products

material