-

Call

-

Email

orbitengineering01@gmail.com

-

Product Grid

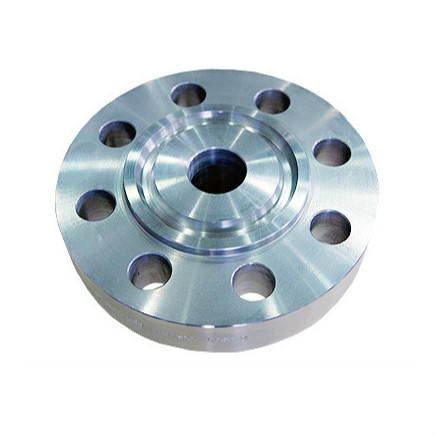

Blind Flanges (BLRF)

Founded in 1991 and built over the years with air and creativity, orbit engineering co. is a powerhouse manufacturer, supplier of Blind Flanges that stand for quality and convenience. We go the extra mile to usher the best services to our customers. Our Blind Flanges are mostly used to seal the end or opening of a pipe, which is why they come without a bore. This is handy for inspection and pressure tests, as it allows quick access to the pipe.

Product Structure

Standard Specication For Blind Flanges

Dimensions : ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Size : 1/2″ (15 NB) to 48″ (1200NB)

Class : 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

DIN : DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629,

DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673

BS : BS4504 , BS4504, BS1560, BS10

Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Material & Grades of Blind Flanges (BLRF) :

Carbon Steel Blind Flanges :

ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706

Low Temperature Carbon Steel Blind Flanges : ASTM A350, LF2, LF3

Alloy Steel Blind Flanges :

ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

Technical Parameters

Dimensions Blind Flanges & Stud Bolts ASME B16.5

| CL | 150 | 300 | 600 | 900 | 1500 | 2500 |

| DIA D |

90 | 95 | 95 | 120 | 120 | 135 |

| B | 9.6 | 12.7 | 14.3 | 22.3 | 22.3 | 30.2 |

| 11.2 | 14.3 | 20.7 | 28.7 | 28.7 | 36.6 | |

| DIA G |

35.1 | 35.1 | 35.1 | 35.1 | 35.1 | 35.1 |

| DIA K |

60.3 | 66.7 | 66.7 | 82.6 | 82.6 | 88.9 |

| NO. L |

4 | 4 | 4 | 4 | 4 | 4 |

| DIA L |

15.9 | 15.9 | 15.9 | 22.2 | 22.2 | 22.2 |

| Stud Bolts Diameter x Length | ||||||

| DIA (in) |

1/2 | 1/2 | 1/2 | 3/4 | 3/4 | 3/4 |

| Len mm |

55 | 65 | 75 | 110 | 110 | 120 |

Notes:

- Dimensions are in millimeters unless otherwise indicated.

- The length of the Stud Bolt does not include the height of the chamfers (points).

|

ANSI/ASME/ASA B16.5 150lb/sq.in. Flange BLIND-RF

|

|||||||

|

ø

|

D

|

b

|

g

|

k

|

Holes

|

l

|

Kg.

|

|

1/2″

|

88,9

|

11,1

|

34,9

|

60,3

|

4

|

15,9

|

0,400

|

|

3/4″

|

98,4

|

12,7

|

42,9

|

69,8

|

4

|

15,9

|

0,700

|

|

1″

|

107,9

|

14,3

|

50,8

|

79,4

|

4

|

15,9

|

0,900

|

|

1 1/4″

|

117,5

|

15,9

|

63,5

|

88,9

|

4

|

15,9

|

1,300

|

|

1 1/2″

|

127,0

|

17,5

|

73,0

|

98,4

|

4

|

15,9

|

1,600

|

|

2″

|

152,4

|

19,0

|

92,1

|

120,6

|

4

|

19,0

|

2,600

|

|

2 1/2″

|

177,8

|

22,2

|

104,8

|

139,4

|

4

|

19,0

|

4,100

|

|

3″

|

190,5

|

23,8

|

127,0

|

152,4

|

4

|

19,0

|

5,000

|

|

3 1/2″

|

215,9

|

23,8

|

139,7

|

177,8

|

8

|

19,0

|

6,400

|

|

4″

|

228,6

|

23,8

|

157,2

|

190,5

|

8

|

19,0

|

7,100

|

|

5″

|

254,0

|

23,8

|

185,7

|

215,9

|

8

|

22,2

|

9,000

|

|

6″

|

279,4

|

25,4

|

215,9

|

241,3

|

8

|

22,2

|

11,800

|

|

8″

|

342,9

|

28,6

|

269,9

|

298,4

|

8

|

22,2

|

21,000

|

|

10″

|

406,4

|

30,2

|

323,4

|

361,9

|

12

|

25,4

|

30,000

|

|

12″

|

482,6

|

31,7

|

381,0

|

431,8

|

12

|

25,4

|

45,000

|

|

14″

|

533,4

|

34,9

|

412,7

|

476,2

|

12

|

28,6

|

59,000

|

|

16″

|

596,9

|

36,5

|

469,9

|

539,9

|

16

|

28,6

|

79,000

|

|

18″

|

635,0

|

39,7

|

533,4

|

577,8

|

16

|

31,7

|

97,000

|

|

20″

|

698,5

|

42,9

|

584,2

|

635,0

|

20

|

31,7

|

124,000

|

|

22″

|

749,3

|

46,0

|

641,2

|

692,1

|

20

|

34,9

|

151,000

|

|

24″

|

812,8

|

47,6

|

692,1

|

749,3

|

20

|

34,9

|

188,000

|

|

ANSI/ASME/ASA B16.5 300lb/sq.in. Flange BLIND-RF

|

|||||||

|

ø

|

D

|

b

|

g

|

k

|

Holes

|

l

|

Kg.

|

|

1/2″

|

95,2

|

14,3

|

34,9

|

66,7

|

4

|

15,9

|

0,700

|

|

3/4″

|

117,5

|

15,9

|

42,9

|

82,5

|

4

|

19,0

|

1,200

|

|

1″

|

123,8

|

17,5

|

50,8

|

88,9

|

4

|

19,0

|

1,500

|

|

1 1/4″

|

133,3

|

19,0

|

63,5

|

98,4

|

4

|

19,0

|

2,000

|

|

1 1/2″

|

155,6

|

20,6

|

73,0

|

114,3

|

4

|

22,2

|

2,900

|

|

2″

|

165,1

|

22,2

|

92,1

|

127,0

|

8

|

19,0

|

3,400

|

|

2 1/2″

|

190,5

|

25,4

|

104,8

|

149,2

|

8

|

22,2

|

5,100

|

|

3″

|

209,5

|

28,6

|

127,0

|

168,3

|

8

|

22,2

|

7,000

|

|

3 1/2″

|

228,6

|

30,2

|

139,7

|

184,1

|

8

|

22,2

|

8,900

|

|

4″

|

254,0

|

31,7

|

157,2

|

200,0

|

8

|

22,2

|

11,800

|

|

5″

|

279,4

|

34,9

|

185,7

|

234,9

|

8

|

22,2

|

15,500

|

|

6″

|

317,5

|

36,5

|

215,9

|

269,9

|

12

|

22,2

|

21,300

|

|

8″

|

381,0

|

41,3

|

269,9

|

330,2

|

12

|

25,4

|

35,200

|

|

10″

|

444,5

|

47,6

|

323,8

|

387,3

|

16

|

28,6

|

57,000

|

|

12″

|

520,7

|

50,8

|

381,0

|

450,8

|

16

|

31,7

|

82,000

|

|

14″

|

584,2

|

54,0

|

412,7

|

514,3

|

20

|

31,7

|

106,000

|

|

16″

|

647,7

|

57,1

|

469,9

|

571,5

|

20

|

34,9

|

140,000

|

|

18″

|

711,2

|

60,3

|

533,4

|

628,6

|

24

|

34,9

|

178,000

|

|

20″

|

774,7

|

63,5

|

584,2

|

685,8

|

24

|

34,9

|

223,000

|

|

22″

|

838,2

|

66,7

|

641,2

|

742,9

|

24

|

41,3

|

270,000

|

|

24″

|

914,4

|

69,8

|

692,1

|

812,8

|

24

|

41,3

|

345,000

|

|

ANSI/ASME/ASA B16.5 600lb/sq.in. Flange BLIND-RF

|

|||||||

|

ø

|

D

|

b

|

g

|

k

|

Holes

|

l

|

Kg.

|

|

1/2″

|

95,2

|

14,3

|

34,9

|

66,7

|

4

|

15,9

|

0,700

|

|

3/4″

|

117,5

|

15,9

|

42,9

|

82,5

|

4

|

19,0

|

1,200

|

|

1″

|

123,8

|

17,5

|

50,8

|

88,9

|

4

|

19,0

|

1,500

|

|

1 1/4″

|

133,3

|

20,6

|

63,5

|

98,4

|

4

|

19,0

|

2,000

|

|

1 1/2″

|

155,6

|

22,2

|

73,0

|

114,3

|

4

|

22,2

|

3,200

|

|

2″

|

165,1

|

25,4

|

92,1

|

127,0

|

8

|

19,0

|

4,300

|

|

2 1/2″

|

190,5

|

28,6

|

104,8

|

149,2

|

8

|

22,2

|

6,000

|

|

3″

|

209,5

|

31,7

|

127,0

|

168,3

|

8

|

22,2

|

8,000

|

|

3 1/2″

|

228,6

|

34,9

|

139,7

|

184,1

|

8

|

25,4

|

10,500

|

|

4″

|

273,0

|

38,1

|

157,2

|

215,9

|

8

|

25,4

|

18,000

|

|

5″

|

330,2

|

44,4

|

185,7

|

266,7

|

8

|

28,6

|

28,500

|

|

6″

|

355,6

|

47,6

|

215,9

|

292,1

|

12

|

28,6

|

35,500

|

|

8″

|

419,1

|

55,6

|

269,9

|

349,2

|

12

|

31,7

|

58,000

|

|

10″

|

508,0

|

63,5

|

323,8

|

431,8

|

16

|

34,9

|

98,000

|

|

12″

|

558,8

|

66,7

|

381,0

|

488,9

|

20

|

34,9

|

125,000

|

|

14″

|

603,2

|

69,8

|

412,7

|

527,0

|

20

|

38,1

|

151,000

|

|

16″

|

685,8

|

76,2

|

469,9

|

603,2

|

20

|

41,3

|

215,000

|

|

18″

|

742,9

|

82,5

|

533,4

|

654,0

|

20

|

44,4

|

287,000

|

|

20″

|

812,8

|

88,9

|

584,2

|

723,9

|

24

|

44,4

|

366,000

|

|

22″

|

869,9

|

95,2

|

641,2

|

777,9

|

24

|

47,6

|

437,000

|

|

24″

|

939,8

|

101,6

|

692,1

|

838,2

|

24

|

50,8

|

532,000

|

Application

ANSI B16.5 Blind Flanges Application

ASME B16.5 Blind Flanges are known to deliver exceptional performance and are generally developed for

meeting the demands. We offer a broad range of Flat Faced Blind Flanges through a network of stock keeping branches. These Blind Flange is use in various industries like :

Stainless Steel Blind Flanges uses in Oil and Gas Pipeline

Blind Raised Face Flanges uses in Chemical Industry

Alloy Steel BLRF Flanges uses in Plumbing

Flat Faced Blind Flanges uses in Heating

Blind Pipe Flanges uses in Water Supply Systems

ANSI B16.5 Blind Forged Flanges uses in Power Plant

Blind Plate Flanges uses in Paper & Pulp Industry

Blind Flange uses in General Purpose Applications

Steel Blind Flanges uses in Fabrication Industry

Blind Flange uses in Food Processing Industry

Blind Flanges uses in Structural Pipe

Related products

ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706