-

Call

-

Email

orbitengineering01@gmail.com

-

Product Grid

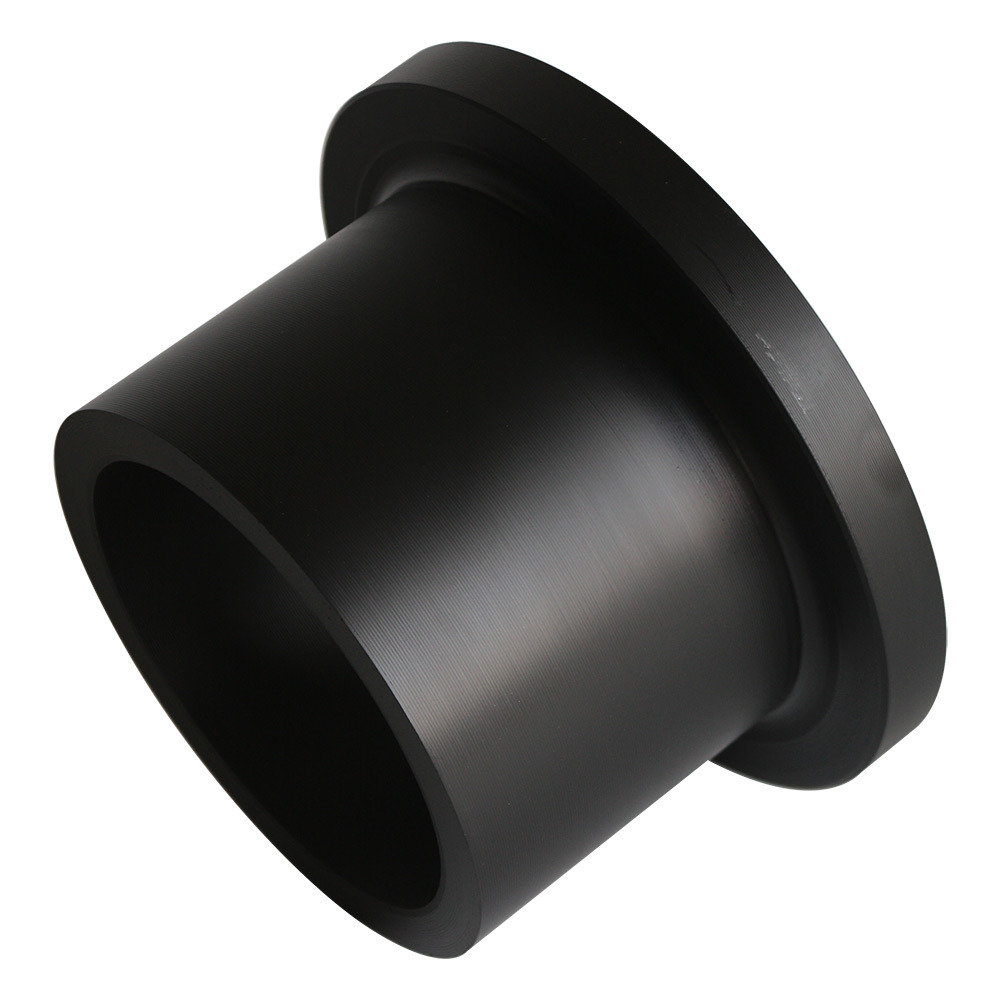

Short Stub End

orbit engineering co. as given an impetus to several industries during the last three decades, especially through its outstanding products and extraordinary services. We are certified to cater to the rigid and stringent requisites of the most critical of industries. We are manufacturers, suppliers of Short Stub Ends, stub ends that have a smaller hub length, as opposed to Long Stub Ends, that have an elongated one. They are alternative to welded ages: they play the role of rotating backup flanges. Manufactured using the best machinery and resources, these Fittings are a cost-effective product as it is not necessary that the material from which the stub end is made matches the piping material. Let us know your industry requirements and we can furnish you customized Stainless Steel Short Stub Ends as well.

Product Structure

Standard Specication For Buttweld Short Stub End

Dimensions : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43

Size : 1/2″NB TO 36 “NB IN

Type : Seamless / ERW / Welded / Fabricated

Thickness : Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and

etc.

Form : Short Stub Ends, Pipe Stub Ends, Butt weld Short Stub Ends.

Material & Grades of Buttweld Short Stub End :

Carbon Steel Buttweld Short Stub End :

ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Low Temperature Carbon Steel Buttweld Short Stub End : ASTM A420 WPL3, A420 WPL6

Alloy Steel Buttweld Short Stub End :

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

Technical Parameters

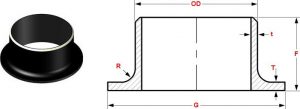

Dimensions Lap Joint Stub Ends schedule STD & XSASME B16.9

| Schedule STD | ||||||

| NPS | OD | T | G | F | R | kg |

| 1/2 | 21.3 | 2.77 | 34.9 | 76.2 | 3.18 | 0.16 |

| 3/4 | 26.7 | 2.87 | 42.9 | 76.2 | 3.18 | 0.23 |

| 1 | 33.4 | 3.38 | 50.8 | 101.6 | 3.18 | 0.29 |

| 1.1/4 | 42.2 | 3.56 | 63.5 | 101.6 | 4.76 | 0.45 |

| 1.1/2 | 48.3 | 3.68 | 73 | 101.6 | 6.35 | 0.54 |

| 2 | 60.3 | 3.91 | 92.1 | 152.4 | 7.94 | 1 |

| 2.1/2 | 73 | 5.16 | 104.8 | 152.4 | 7.94 | 1.5 |

| 3 | 88.9 | 5.49 | 127 | 152.4 | 9.53 | 2.1 |

| 3.1/2 | 101.6 | 5.74 | 139.7 | 152.4 | 9.53 | 2.5 |

| 4 | 114.3 | 6.02 | 157.2 | 152.4 | 11.11 | 3 |

| 5 | 141.3 | 6.55 | 185.7 | 203.2 | 11.11 | 5.4 |

| 6 | 168.3 | 7.11 | 215.9 | 203.2 | 12.7 | 7.3 |

| 8 | 219.1 | 8.18 | 269.9 | 203.2 | 12.7 | 11.6 |

| 10 | 273.1 | 9.27 | 323.9 | 254 | 12.7 | 18 |

| 12 | 323.9 | 9.53 | 381 | 254 | 12.7 | 21 |

| 14 | 355.6 | 9.53 | 412.8 | 304.8 | 12.7 | 28 |

| 16 | 406.4 | 9.53 | 469.9 | 304.8 | 12.7 | 34 |

| 18 | 457.2 | 9.53 | 533.4 | 304.8 | 12.7 | 39 |

| 20 | 508 | 9.53 | 584.2 | 304.8 | 12.7 | 44 |

| 24 | 609.6 | 9.53 | 692.2 | 304.8 | 12.7 | 57 |

| Schedule XS | ||||||

| NPS | OD | T | G | F | R | kg |

| 1/2 | 21.3 | 3.73 | 34.9 | 76.2 | 3.18 | 0.2 |

| 3/4 | 26.7 | 3.91 | 42.9 | 76.2 | 3.18 | 0.3 |

| 1 | 33.4 | 4.55 | 50.8 | 101.6 | 3.18 | 0.4 |

| 1.1/4 | 42.2 | 4.85 | 63.5 | 101.6 | 4.76 | 0.6 |

| 1.1/2 | 48.3 | 5.08 | 73 | 101.6 | 6.35 | 0.7 |

| 2 | 60.3 | 5.54 | 92.1 | 152.4 | 7.94 | 1.4 |

| 2.1/2 | 73 | 7.01 | 104.8 | 152.4 | 7.94 | 2 |

| 3 | 88.9 | 7.62 | 127 | 152.4 | 9.53 | 2.9 |

| 3.1/2 | 101.6 | 8.08 | 139.7 | 152.4 | 9.53 | 3.4 |

| 4 | 114.3 | 8.56 | 157.2 | 152.4 | 11.11 | 4.1 |

| 5 | 141.3 | 9.53 | 185.7 | 203.2 | 11.11 | 7.5 |

| 6 | 168.3 | 10.97 | 215.9 | 203.2 | 12.7 | 10 |

| 8 | 219.1 | 12.7 | 269.9 | 203.2 | 12.7 | 16 |

| 10 | 273.1 | 12.7 | 323.9 | 254 | 12.7 | 24 |

| 12 | 323.9 | 12.7 | 381 | 254 | 12.7 | 29 |

| 14 | 355.6 | 12.7 | 412.8 | 304.8 | 12.7 | 38 |

| 16 | 406.4 | 12.7 | 469.9 | 304.8 | 12.7 | 43 |

| 18 | 457.2 | 12.7 | 533.4 | 304.8 | 12.7 | 49 |

| 20 | 508 | 12.7 | 584.2 | 304.8 | 12.7 | 63 |

| 24 | 609.6 | 12.7 | 692.2 | 304.8 | 12.7 | 76 |

DIMENSIONAL TOLERANCES OF STUB ENDS ASME B16.9

| Nominal Pipe Size | 1/2 up to 2.1/2 | 3 to 3.1/2 | 4 | 5 to 8 | 10 to 18 | 20 to 24 |

| Outside Diameter at Welding End (OD) | 1.6 | 1.6 | 1.6 | 2.29 | 4.06 | 6.35 |

| -0.8 | -1.6 | -3.05 | -4.83 | |||

| Overall Length (F) | 1.6 | 1.6 | 1.6 | 1.6 | 2 | 2 |

| Outside Diameter of Lap (G) | 0 | 0 | 0 | 0 | 0 | 0 |

| -0.76 | -0.76 | -0.76 | -0.76 | -1.6 | -1.6 | |

| Thickness of Lap (T) | 1.52 | 1.52 | 1.52 | 1.52 | 1.52 | 1.52 |

| 0 | 0 | 0 | 0 | 0 | 0 | |

| Fillet Radius of Lap (R) | 0 | 0 | 0 | 0 | 0 | 0 |

| -0.76 | -0.76 | -1.6 | -1.6 | -1.6 | -1.6 | |

| Wall Thickness (t) | Not less than 87.5% of Nominal Wall Thickness | |||||

| Dimensional tolerances are in millimeters unless otherwise indicated. | ||||||

Related products

ASTM A234, ASME SA234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.