-

Call

-

Email

orbitengineering01@gmail.com

-

Product Grid

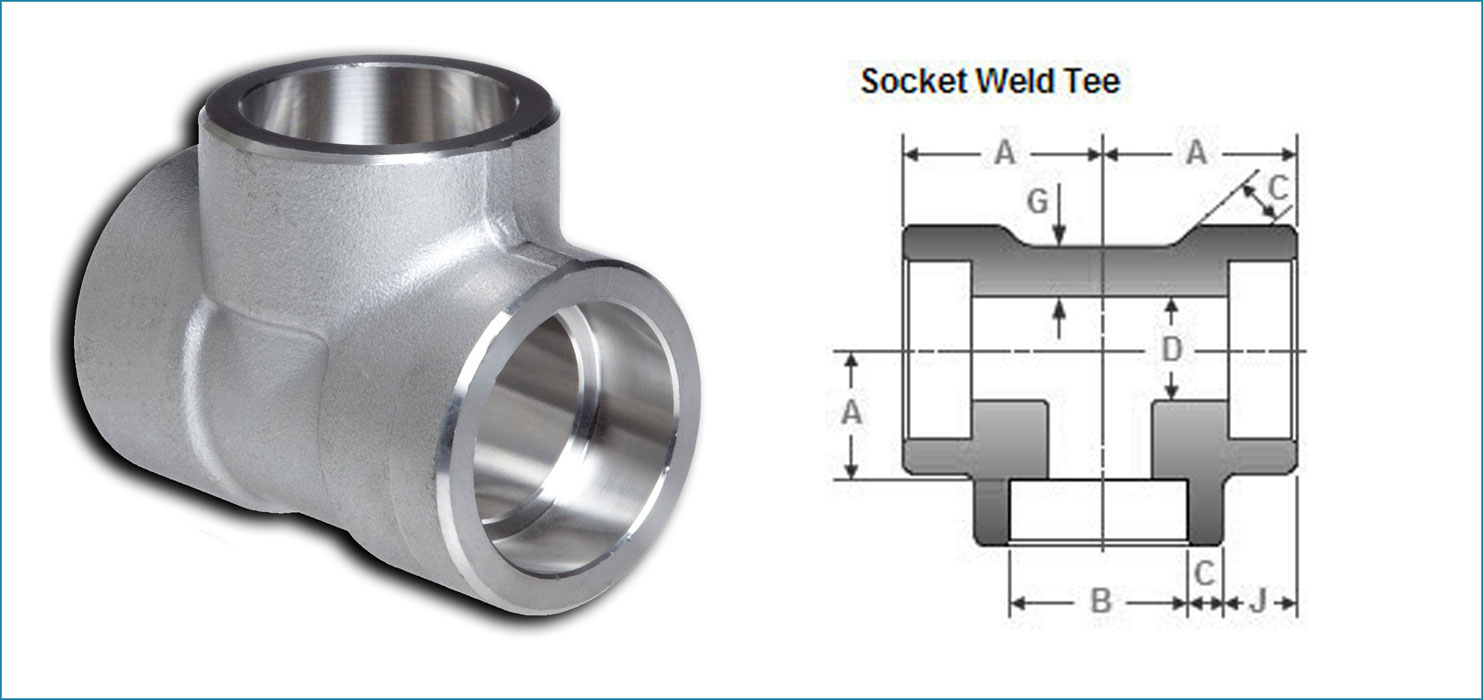

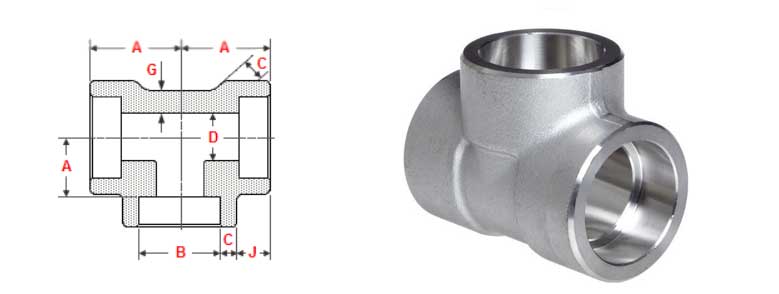

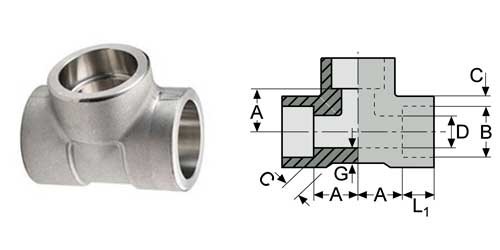

Socket Weld Tee

description

Description

Orbit Engineering co. is authoritative manufacturer and supplier of ASME B16.11 Socket Weld Tee, manufactured as per international quality parameters. Our Socket Weld Tee Fittings comes in a variety of classes and material grades for various industrial applications. Our offered Forged Socket Weld Equal Tee makes 90° branch from the main run of pipe.

Orbit Engineering co. is authoritative manufacturer and supplier of ASME B16.11 Socket Weld Tee, manufactured as per international quality parameters. Our Socket Weld Tee Fittings comes in a variety of classes and material grades for various industrial applications. Our offered Forged Socket Weld Equal Tee makes 90° branch from the main run of pipe.

We are also the largest independent stockholder of Socket Weld Equal Tee with huge ready stock. We supply these Socket Weld Tees to various industrial applications like chemical processing, oil refineries, petrochemical and many other industries. ANSI B16.11 Forged Socket Weld Tee is leakage proof and corrosion-resistant. Socket Weld Equal Tees are used for toxic lines conveying flammable or expensive material where no leakage can be permitted, and for steam 300 to 600 PSI.

|

Product Structure

ANSI/ASME B16.11 Socket Weld Tee Standard Specification

| Dimensions | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Size | 1/2″NB TO 4″NB IN |

| Class | 3000 LBS, 6000 LBS, 9000 LBS |

| Type | Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT |

| Form | Sockte Weld Tee, Socket Weld Equal Tee |

| Production Grades | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupro Nickel |

Manufacturing Standards of Socket Weld Equal Tee

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

Forged Socket Weld Tee Material Grades

Nickel Alloy Forged Socket Weld Tee :

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200) , UNS 2201 (NICKEL 201 ) , UNS 4400 (MONEL 400 ) , UNS 8020 ( ALLOY 20 / 20 CB 3 ) , UNS 8825 INCONEL (825) , UNS 6600 (INCONEL 600 ) , UNS 6601 (INCONEL 601) , UNS 6625 (INCONEL 625) , UNS 10276 (HASTELLOY C 276)

.

Carbon Steel Forged Socket Weld Tee :

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Alloy Steel Forged Socket Weld Tee :

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

ASME B16.11 Forged Socket Weld Tee Available Types

| Forged Socket weld Tee | Socket Welding Reducing Tee |

| 150 lb. Socket Weld Fittings Pipe Tee | 2 inch Socket weld Tee |

| ASME B16.11 Socket weld Equal Tee | 3000LB Socket Weld Tee |

| Socket Weld Tee Fittings | class 6000 Socket Weld Forged Tee |

| ANSI B16.11 Forged Socket Weld Tee | BS 3799 Forged Socket Weld Tee |

| Forged Socket weld Equal Tee | Socket Weld Equal Tee Weight |

| Socket weld Tee Reducer | High Quality Socket weld Tee |

| 1 inch Socket Weld Tee | Socket Weld Pipe Tee |

|

Technical Parameters

ANSI/ASME B16.11 SOCKET WELD TEE DIMENSIONS

Socket Weld Equal Tee Dimensions

Class 3000 Socket Weld Tee Dimensions NPS 1/2 to 2

| NPS | Socket Bore | Depth Socket | Bore dia |

| B | J | D | |

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

| 1.1/4 | 42.80 42.55 |

13 | 35.8 34.3 |

| 1.1/2 | 48.90 48.65 |

13 | 41.7 40.1 |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

| 2.1/2 | 74.20 73.80 |

16 | 64.2 61.2 |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

| 1/2 | 4.65 4.10 |

3.75 | 15.5 |

| 3/4 | 4.90 4.25 |

3.90 | 19.5 |

| 1 | 5.70 5.00 |

4.55 | 22 |

| 1.1/4 | 6.05 5.30 |

4.85 | 27 |

| 1.1/2 | 6.35 5.55 |

5.10 | 32 |

| 2 | 6.95 6.05 |

5.55 | 38 |

| 2.1/2 | 8.75 7.65 |

7.00 | 41.5 |

| 3 | 9.50 8.30 |

7.60 | 57.5 |

| 4 | 10.70 9.35 |

8.55 | 66.5 |

Class 6000 Socket Weld Tee Dimensions NPS 1/2 to 2

| NPS | Socket Bore | Depth Socket | Bore dia |

| B | J | D | |

| 1/2 | 21.95 21.70 |

10 | 12.5 11 |

| 3/4 | 27.30 27.05 |

13 | 16.3 14.8 |

| 1 | 34.05 33.80 |

13 | 21.5 19.9 |

| 1.1/4 | 42.80 42.55 |

13 | 30.2 28.7 |

| 1.1/2 | 48.90 48.65 |

13 | 34.7 33.2 |

| 2 | 61.35 61.10 |

16 | 43.6 42.1 |

| 1/2 | 5.95 5.20 |

4.80 | 19.5 |

| 3/4 | 6.95 6.05 |

5.55 | 22.5 |

| 1 | 7.90 6.95 |

6.35 | 27 |

| 1.1/4 | 7.90 6.95 |

6.35 | 32 |

| 1.1/2 | 8.90 7.80 |

7.15 | 38 |

| 2 | 10.90 9.50 |

8.75 | 41 |

General notes:

- Dimensions are in millimeters unless otherwise indicated.

- Socket Bore (B) – Maximum and minimum dimensions.

- Bore Diameter (D) – Maximum and minimum dimensions.

- Socket wall thickness – (C) – Average of Socket wall thickness.

- Dimensional tolerances center to the bottom of the socket – (A)

NPS 1/2 and NPS 3/4 = +/- 1.5 mm

NPS 1 to NPS 2 = +/- 2 mm

NPS 2.1/2 to NPS 4 = +/- 2.5 mm

Socket weld Equal Tee Weight

| Nominal pipe size | B | L1 | C | G | D | A |

Weight

|

|---|---|---|---|---|---|---|---|

| in. | mm | socket | mm | mm | mm | mm | ~kg/pce |

| 1/4 3/8 1/2 3/4 |

14.20

17.60 21.80 27.20 |

9.53

9.53 9.53 12.50 |

3.30

3.51 4.09 4.27 |

3.02

3.20 3.73 3.91 |

8.86

12.14 15.42 20.55 |

11.11

13.49 15.88 19.05 |

0.11

0.16 0.34 0.41 |

| 1 1¼ 1½ 2 |

33.90

42.70 48.80 61.20 |

12.50

12.50 12.50 16.00 |

4.98

5.28 5.54 6.05 |

4.55

4.85 5.08 5.54 |

26.26

34.67 40.51 52.12 |

22.23

26.99 31.75 38.10 |

0.65

0.95 1.33 2.20 |

|

Application

Forged Socket Tee Application

ASME B16.11 45 Degree Socket weld Tee is known to deliver exceptional performance and are generally

developed for meeting the demands. We offer a broad range of Forged 45 Degree Socket weld Tee through a

network of stock-keeping branches. This 45Deg. Socket weld Tee is used in various industries like :

Stainless Steel 45° Forged Tee uses in Oil and Gas Pipeline

45° Forged Pipe Tee uses in Chemical Industry

Alloy Steel 45° Tee uses in Plumbing

Forged 45 Degree Pipe Tee uses in Heating

45 Degree Forged Tee uses in Water Supply Systems

ANSI B16.9 Forged 45° Pipe Tee uses in Power Plant

45° Tee uses in Paper & Pulp Industry

45° Degree Tee uses in General Purpose Applications

Forged 45° Long Radius Tee uses in Fabrication Industry

45° Forged Tee uses in Food Processing Industry

Forged 45° Short Radius Tee uses in Structural Pipe

Related products

material