-

Call

-

Email

orbitengineering01@gmail.com

-

Product Grid

Socket Weld Unequal Tee

description

Description

An ISO certified company, Orbit Engineering co, is following international standards to provide the best for its customers who get enticed with the additional services provided to them. Socket Weld Unequal Tees are used to connect the pipes of different diameters and change the direction of the pipe . Another term for Unequal Tee is Reducing Tee. In the case of Stainless Steel Socket Weld Unequal Tees, the branch pipe diameter is smaller than the running pipe. The branch is the inlet of the Flow. These ASME B16.11

An ISO certified company, Orbit Engineering co, is following international standards to provide the best for its customers who get enticed with the additional services provided to them. Socket Weld Unequal Tees are used to connect the pipes of different diameters and change the direction of the pipe . Another term for Unequal Tee is Reducing Tee. In the case of Stainless Steel Socket Weld Unequal Tees, the branch pipe diameter is smaller than the running pipe. The branch is the inlet of the Flow. These ASME B16.11

Socket Weld Reducing Tees are capable of handling high pressures or temperatures of the liquid owing through them. Orbit Engineeringco. flawlessly produces ANSI B16.11 Socket Weld Unequal Tees that have

zero defects and are promptly delivered to the clients with any additional changes if the client demands so.

|

Product Structure

Standard Specification For Forged Socket Weld Unequal Tee

Dimensions : ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799

Size : 1/8″ NB TO 4″ NB

Pressure Class : 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS

Form : Unequal Tee, Forged Unequal Tee, Reducing Tee.

Material & Grades of Forged Socket Weld Unequal Tee :

Carbon Steel Forged Socket Weld Unequal Tee :ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B,API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Alloy Steel Forged Socket Weld Unequal Tee :

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM /

ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

ASME B16.11 Forged Socket Weld Unequal Tee Available Types

| Forged Socket weld Unequal Tee | Socket Welding Unequal Tee |

| 150 lb. Socket Weld Forged Tee | 2 inch Socket weld Tee |

| ASME B16.11 Socket weld Reducing Tee | 3000LB Socket Weld Unequal Tee |

| Socket Weld Unequal Tee Fittings | Class 6000 Socket Weld Forged Tee |

| ANSI B16.11 Forged Socket Weld Unequal Tee | BS 3799 Forged Socket Weld Unequal Tee |

| Forged Socket weld Reducing Tee | Socket Weld Reducing Tee Weight |

| Forged Steel Socket weld Reducing Tee | High Quality Socket weld Forged Tee |

| 1 inch Socket Weld Unequal Tee | Socket Weld Forged Pipe Tee |

|

Technical Parameters

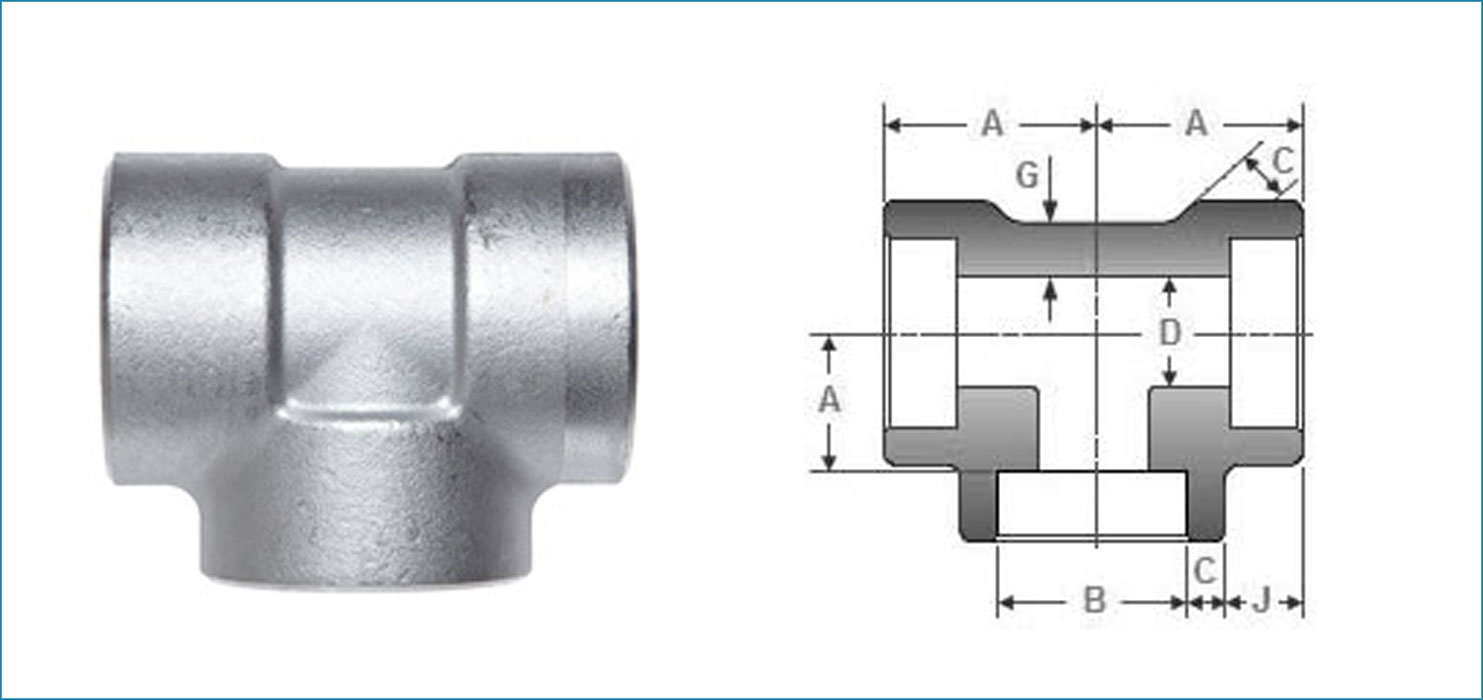

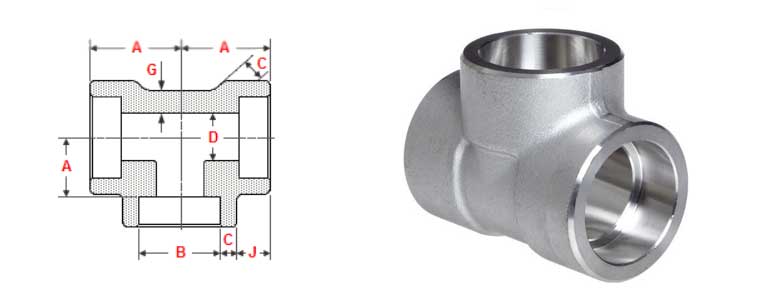

ANSI/ASME B16.11 SOCKET WELD UNEQUAL TEE DIMENSIONS

Socket Weld Reducing Tee Dimensions

Socket Weld Unequal Tee Drawing

Class 3000 Socket Weld Unequal Tee Dimensions NPS 1/2 to 2

| NPS | Socket Bore | Depth Socket | Bore dia |

| B | J | D | |

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

| 1.1/4 | 42.80 42.55 |

13 | 35.8 34.3 |

| 1.1/2 | 48.90 48.65 |

13 | 41.7 40.1 |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

| 2.1/2 | 74.20 73.80 |

16 | 64.2 61.2 |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

| 1/2 | 4.65 4.10 |

3.75 | 15.5 |

| 3/4 | 4.90 4.25 |

3.90 | 19.5 |

| 1 | 5.70 5.00 |

4.55 | 22 |

| 1.1/4 | 6.05 5.30 |

4.85 | 27 |

| 1.1/2 | 6.35 5.55 |

5.10 | 32 |

| 2 | 6.95 6.05 |

5.55 | 38 |

| 2.1/2 | 8.75 7.65 |

7.00 | 41.5 |

| 3 | 9.50 8.30 |

7.60 | 57.5 |

| 4 | 10.70 9.35 |

8.55 | 66.5 |

Class 6000 Socket Weld Unequal Tee Dimensions NPS 1/2 to 2

| NPS | Socket Bore | Depth Socket | Bore dia |

| B | J | D | |

| 1/2 | 21.95 21.70 |

10 | 12.5 11 |

| 3/4 | 27.30 27.05 |

13 | 16.3 14.8 |

| 1 | 34.05 33.80 |

13 | 21.5 19.9 |

| 1.1/4 | 42.80 42.55 |

13 | 30.2 28.7 |

| 1.1/2 | 48.90 48.65 |

13 | 34.7 33.2 |

| 2 | 61.35 61.10 |

16 | 43.6 42.1 |

| 1/2 | 5.95 5.20 |

4.80 | 19.5 |

| 3/4 | 6.95 6.05 |

5.55 | 22.5 |

| 1 | 7.90 6.95 |

6.35 | 27 |

| 1.1/4 | 7.90 6.95 |

6.35 | 32 |

| 1.1/2 | 8.90 7.80 |

7.15 | 38 |

| 2 | 10.90 9.50 |

8.75 | 41 |

General notes:

- Dimensions are in millimeters unless otherwise indicated.

- Socket Bore (B) – Maximum and minimum dimensions.

- Bore Diameter (D) – Maximum and minimum dimensions.

- Socket wall thickness – (C) – Average of Socket wall thickness.

- Dimensional tolerances center to bottom of socket – (A)

NPS 1/2 and NPS 3/4 = +/- 1.5 mm

NPS 1 to NPS 2 = +/- 2 mm

NPS 2.1/2 to NPS 4 = +/- 2.5 mm

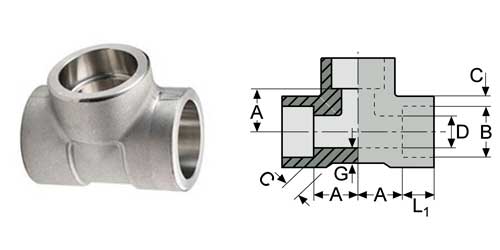

Socket weld Reducing Tee Weight

| Nominal pipe size | B | L1 | C | G | D | A |

Weight

|

|---|---|---|---|---|---|---|---|

| in. | mm | socket | mm | mm | mm | mm | ~kg/pce |

| 1/4 3/8 1/2 3/4 |

14.20

17.60 21.80 27.20 |

9.53

9.53 9.53 12.50 |

3.30

3.51 4.09 4.27 |

3.02

3.20 3.73 3.91 |

8.86

12.14 15.42 20.55 |

11.11

13.49 15.88 19.05 |

0.11

0.16 0.34 0.41 |

| 1 1¼ 1½ 2 |

33.90

42.70 48.80 61.20 |

12.50

12.50 12.50 16.00 |

4.98

5.28 5.54 6.05 |

4.55

4.85 5.08 5.54 |

26.26

34.67 40.51 52.12 |

22.23

26.99 31.75 38.10 |

0.65

0.95 1.33 2.20 |

|

Application

Forged Socket Weld Unequal Tee Application

ASME B16.11 Socket weld Unequal Tee are known to deliver exceptional performance and are generally

developed for meeting the demands. We offer a broad range of Forged Socket weld Reducing Tee through a

network of stock-keeping branches. These Forged Socket weld Unequal Tee is use in various industries

like :

Stainless Steel Forged Socket weld Unequal Tee uses in Oil and Gas Pipeline

Forged Socket weld Unequal Tee uses in Chemical Industry

Alloy Steel Socket weld Unequal Tee uses in Plumbing

Forged Socket weld Unequal Tee uses in Heating

Socket weld Forged Reducing Tee uses in Water Supply Systems

ANSI B16.11 Forged Socket weld Unequal Tee uses in Power Plant

Socket weld Unequal Tee uses in Paper & Pulp Industry

Forged Socket weld Unequal Tee uses in General Purpose Applications

Forged Socket weld Reducing Tee uses in Fabrication Industry

Forged Socket weld Unequal Tee uses in Food Processing Industry

Forged Socket weld Unequal Tee uses in Structural Pipe

|

Related products

material