-

Call

-

Email

orbitengineering01@gmail.com

-

Product Grid

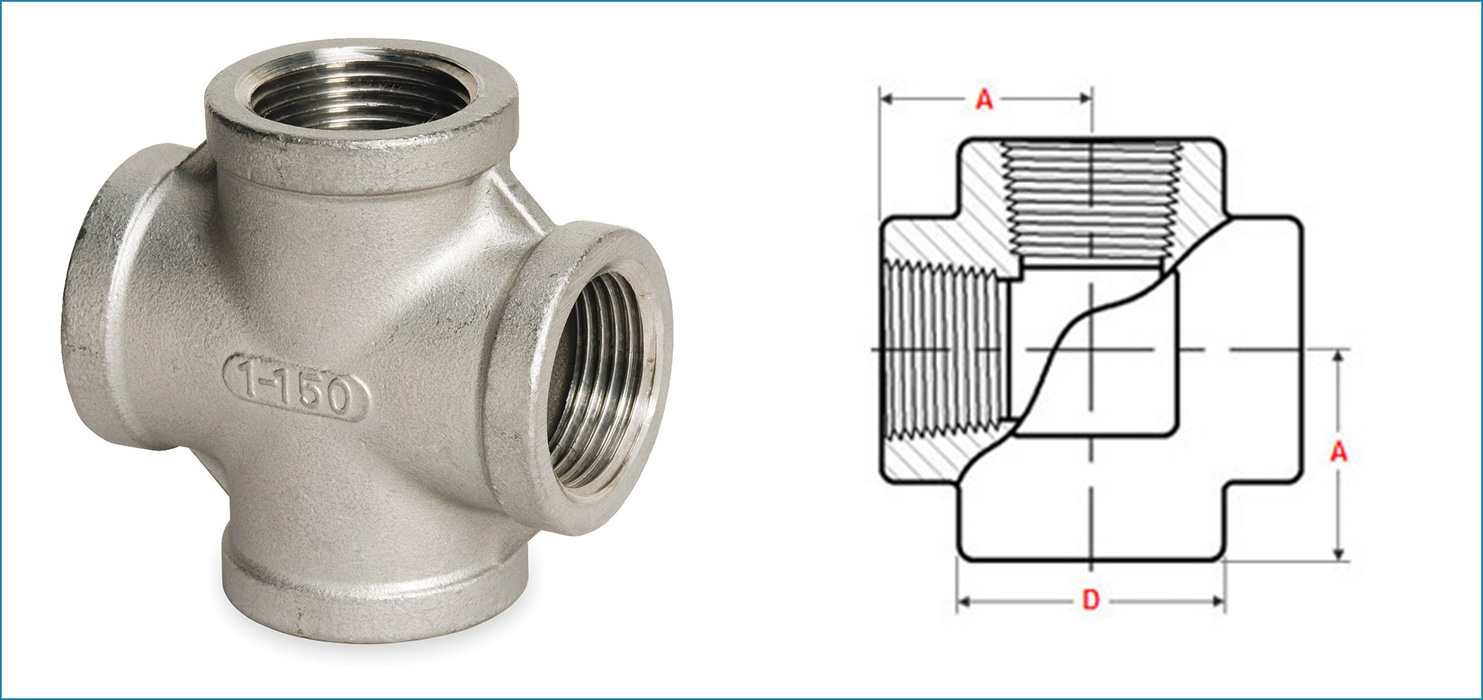

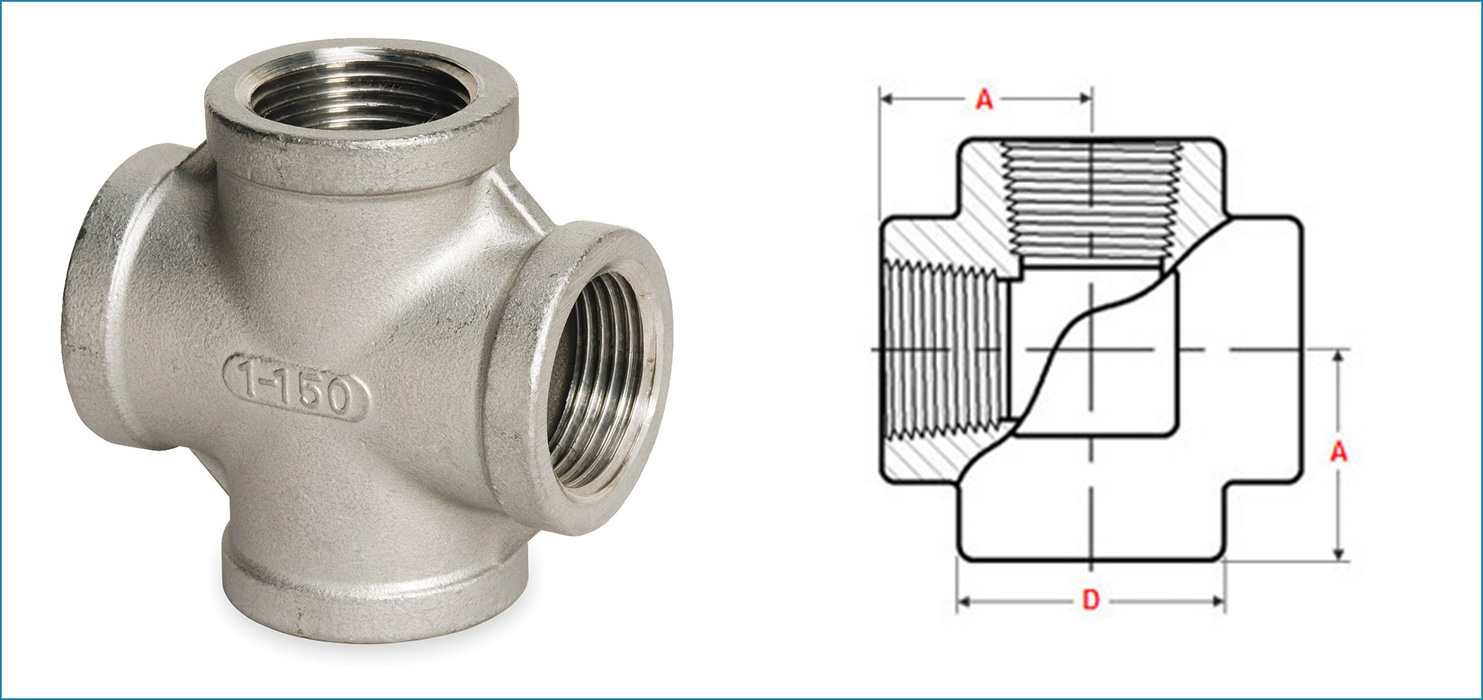

Threaded / Screwed Cross

description

Description

Orbit Engineering co. is leading manufacturer, stockist and supplier of Threaded / Screwed Cross Fittings. It is a company that has received ISO certification and one who provides ultimate convenience to its customers. Threaded Cross fittings make a 90° the branch from the main run of the pipe. It can be used for providing leak-free and torque free sealing in any piping or tubing connection. It is a fitting that is rarely used in a piping system but is an essential part of it nonetheless. Stainless Steel Screwed Cross has two types; straight and reducing. These fittings have one inlet and three outlets or vice versa.

Orbit Engineering co. is leading manufacturer, stockist and supplier of Threaded / Screwed Cross Fittings. It is a company that has received ISO certification and one who provides ultimate convenience to its customers. Threaded Cross fittings make a 90° the branch from the main run of the pipe. It can be used for providing leak-free and torque free sealing in any piping or tubing connection. It is a fitting that is rarely used in a piping system but is an essential part of it nonetheless. Stainless Steel Screwed Cross has two types; straight and reducing. These fittings have one inlet and three outlets or vice versa.

|

Product Structure

ANSI/ASME B16.11 Threaded Pipe Cross Standard Specification

| Dimensions | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Size | 1/8″~4″ (DN6~DN100) |

| Class | 3000 LBS, 6000 LBS, 9000 LBS |

| Type | Socket Weld (S/W) & SCREWED (SCRD) – NPT, BSP, BSPT |

| Form | Threaded Cross, Threaded Pipe Cross, Threaded Equal Cross |

| Value Added Services: | Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering |

| Production Grades: | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupro Nickel |

Manufacturing Standards of Threaded Equal Cross

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

ASME B16.11 Threaded Cross Material Grades

Carbon Steel Forged Threaded Cross:

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR. A & B, ASTM A 106 GR. A, B & C. API 5L GR. B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM / ASME A 691 GR A, B & C

Alloy Steel Forged Threaded Equal Cross :

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

Technical Parameters

ANSI/ASME B16.11 THREADED CROSS DIMENSIONS

Threaded Pipe Cross Dimensions Chart

Threaded Cross Dimensions NPS 1/2 to 4 Class 2000

| NPS | Min Length of Thread | Outside Dia of Band D |

Center to End A |

Min WT |

|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 33 | 28 | 3.18 |

| 3/4 | 12.7 | 13.9 | 38 | 33 | 3.18 |

| 1 | 14.7 | 17.3 | 46 | 38 | 3.68 |

| 1.1/4 | 17 | 18 | 56 | 44 | 3.89 |

| 1.1/2 | 17.8 | 18.4 | 62 | 51 | 4.01 |

| 2 | 19 | 19.2 | 75 | 60 | 4.27 |

| 2.1/2 | 23.6 | 28.9 | 92 | 76 | 5.61 |

| 3 | 25.9 | 30.5 | 109 | 86 | 5.99 |

| 4 | 27.7 | 33 | 146 | 106 | 6.55 |

Threaded Equal Cross Class 3000 Dimensions NPS 1/2 to 4

| NPS | Min Length of Thread | Outside Dia of Band D |

Center to End A |

Min WT |

|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 38 | 33 | 4.09 |

| 3/4 | 12.7 | 13.9 | 46 | 38 | 4.32 |

| 1 | 14.7 | 17.3 | 56 | 44 | 4.98 |

| 1.1/4 | 17 | 18 | 62 | 51 | 5.28 |

| 1.1/2 | 17.8 | 18.4 | 75 | 60 | 5.56 |

| 2 | 19 | 19.2 | 84 | 64 | 7.14 |

| 2.1/2 | 23.6 | 28.9 | 102 | 83 | 7.65 |

| 3 | 25.9 | 30.5 | 121 | 95 | 8.84 |

| 4 | 27.7 | 33 | 152 | 114 | 11.18 |

Threaded Cross Dimensions NPS 1/2 to 4 Class 6000

| NPS | Min Length of Thread | Outside Dia of Band D |

Center to End A |

Min WT |

|

| B | J | ||||

| 1/2 | 10.9 | 13.6 | 46 | 38 | 8.15 |

| 3/4 | 12.7 | 13.9 | 56 | 44 | 8.53 |

| 1 | 14.7 | 17.3 | 62 | 51 | 9.93 |

| 1.1/4 | 17 | 18 | 75 | 60 | 10.59 |

| 1.1/2 | 17.8 | 18.4 | 84 | 64 | 11.07 |

| 2 | 19 | 19.2 | 102 | 83 | 12.09 |

| 2.1/2 | 23.6 | 28.9 | 121 | 95 | 15.29 |

| 3 | 25.9 | 30.5 | 146 | 106 | 16.64 |

| 4 | 27.7 | 33 | 152 | 114 | 18.67 |

General notes:

- Dimensions are in millimeters unless otherwise indicated.

- Dimension B is minimum length of perfect thread.

The length of useful thread (B plus threads with fully formed roots and flat crests) shall not be less than J.

ASME B16.11 Threaded Cross Weight

| Class 2000 | Nominal | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 |

| Pipe | |||||||||||||

| Size | |||||||||||||

| A | – | 7/8 | 31/32 | 1 1/8 | 1 5/16 | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 3 | 3 3/8 | 4 3/16 | |

| B | – | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/16 | 4 5/16 | 5 3/4 | |

| Wt | – | 0.5 | 0.46 | 0.777 | 1.125 | 1.688 | 2.45 | 3.188 | 5.56 | 16.438 | 19.5 | 32.688 | |

| Class 3000 | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| A | 7/8 | 31/32 | 1 1/8 | 1 5/16 | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 2 1/2 | 3 1/4 | 3 3/4 | 4 1/2 | |

| B | 29/32 | 1 1/16 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 6 | |

| Wt | 0.438 | 0.567 | 0.97 | 1.5 | 2.5 | 3.62 | 4.125 | 6.5 | 8.125 | 16.75 | 25.675 | 32 | |

| Class 6000 | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1 1/4 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | |

| A | 31/32 | 1 1/8 | 1 5/16 | 1 1/2 | 1 3/4 | 2 | 2 3/8 | 2 1/2 | 3 1/4 | 3 3/4 | 4 3/16 | 4 1/2 | |

| B | 1 1/6 | 1 5/16 | 1 9/16 | 1 27/32 | 2 7/32 | 2 1/2 | 3 1/32 | 3 11/32 | 4 | 4 3/4 | 5 3/4 | 6 | |

| Wt | 0.563 | 1.188 | 1.5 | 2.75 | 4.313 | 6.625 | 10.75 | 11.5 | 22.188 | 27.5 | 54 | 43.5 | |

|

Application

Forged Threaded / Screwed Equal Cross Application

ASME B16.11 Threaded Cross is known to deliver exceptional performance and are generally developed for

meeting the demands. We offer a broad range of Forged Screwed Cross through a network of stock-keeping branches. This Forged Threaded Cross is used in various industries like :

Stainless Steel Forged Threaded Cross uses in Oil and Gas Pipeline

Forged Threaded Cross uses in Chemical Industry

Alloy Steel Threaded Equal Cross uses in Plumbing

Forged Screwed Equal Cross uses in Heating

Threaded Forged Equal Cross uses in Water Supply Systems

ANSI B16.11 Forged Threaded Cross uses in Power Plant

Threaded Equal Cross uses in Paper & Pulp Industry

Forged Screwed Equal Cross uses in General Purpose Applications

Forged Threaded Cross uses in Fabrication Industry

Forged Screwed Equal Cross uses in Food Processing Industry

Forged Threaded Equal Cross uses in Structural Pipe

|

Related products

material