-

Call

-

Email

orbitengineering01@gmail.com

-

Product Grid

Tongue & Groove Flanges

orbit engineering co. is a manufacturer and supplier of Tongue & Groove Flanges that define finesse and quality. We are an ISO enterprise that engages in providing quality piping solutions through ground-breaking innovation and hard work. , the Tongue Flange is manufactured with a raised ring that is machined into its face. The Groove Flange is produced with a matching depression machined onto its face. In order to have a watertight connection, it is important to match the faces of these flanges. Alloy 20 Groove & Tongue Flanges are self-aligning; they do not come in contact with the inner fluid or gas of the tube or pipe. Instantly, they are free from any corrosion.

Description

Product Structure

Tongue and Groove Flange Face, Gasket for Tongue and Groove Flange, tongue-and-groove (t&g) flange, tongue and groove flange joint

large tongue and groove flange dimensions, tongue and groove type flange, tongue and groove flange applications

ANSI/ASME B16.5 Groove and Tongue Flange Standard Specification

| Dimensions | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| DIN | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673 |

| BS | BS4504 , BS4504, BS1560, BS10 |

| Class | 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc. |

| Flange Face Type | Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

ASME B16.5 Tongue and Groove Flange Material Specification

Carbon Steel Tongue and Groove Flange:

ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706

Low Temperature Carbon Steel Groove and Tongue Flange: ASTM A350, LF2, LF3

Alloy Steel Groove and Tongue Flange:

ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

|

Technical Parameters

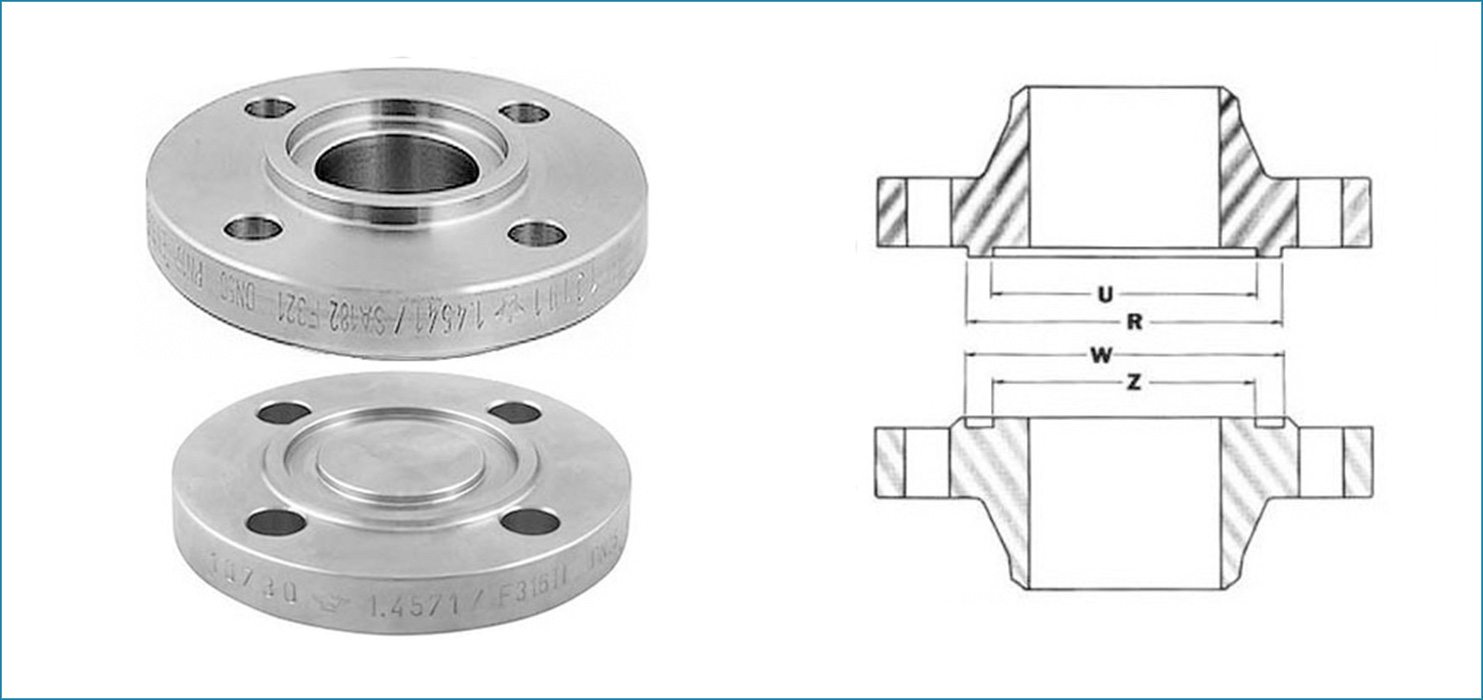

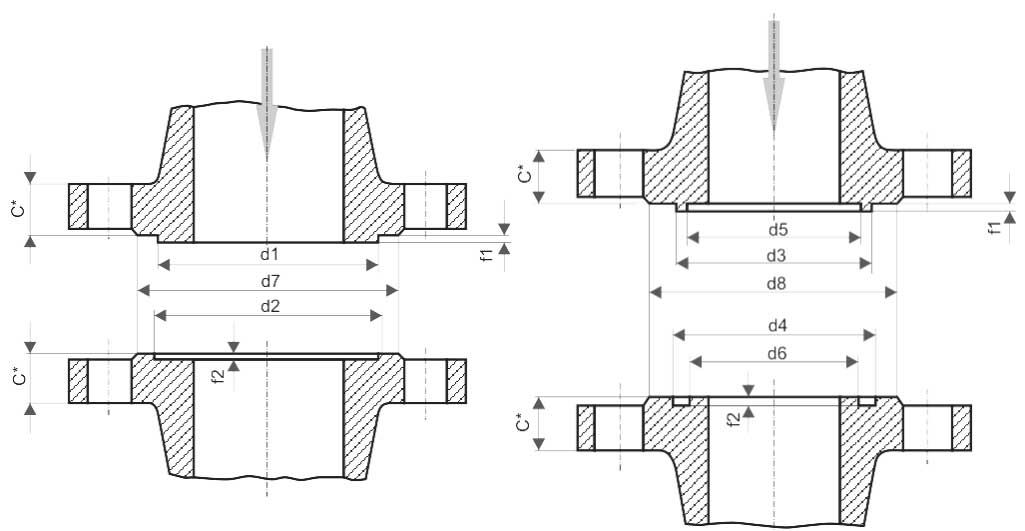

ANSI B16.5 TONGUE AND GROOVE FLANGE DIMENSIONS

| DN | d1 | d2 | d3 | d4 | d5 | d6 | d7 | d8 | f1 | f2 |

| ½” | 1,38 (35,1) |

1,44 (36,6) |

1,38 (35,1) |

1,44 (36,6) |

1,00 (25,4) |

0,94 (23,9) |

1,81 (46,0) |

1,75 (44,5) |

0,25 (6,4) |

0,19 (4,8) |

| ¾” | 1,69 (42,9) |

1,75 (44,5) |

1,69 (42,9) |

1,75 (44,5) |

1,31 (33,3) |

1,25 (31,8) |

2,12 (53,8) |

2,06 (52,3) |

0,25 (6,4) |

0,19 (4,8) |

| 1″ | 2,00 (50,8) |

2,06 (52,3) |

1,88 (47,7) |

1,94 (49,3) |

1,50 (38,1) |

1,44 (36,6) |

2,44 (62,0) |

2,25 (57,2) |

0,25 (6,4) |

0,19 (4,8) |

| 1¼” | 2,50 (63,5) |

2,56 (65,0) |

2,25 (57,2) |

2,31 (58,7) |

1,88 (47,8) |

1,81 (46,0) |

2,94 (74,7) |

2,62 (66,6) |

0,25 (6,4) |

0,19 (4,8) |

| 1½” | 2,88 (73,2) |

2,94 (74,7) |

2,50 (63,5) |

2,56 (65,0) |

2,12 (53,8) |

2,06 (52,3) |

3,31 (84,1) |

2,88 (73,2) |

0,25 (6,4) |

0,19 (4,8) |

| 2″ | 3,62 (92,0) |

3,69 (93,7) |

3,25 (82,6) |

3,31 (84,1) |

2,88 (73,0) |

2,81 (71,4) |

4,06 (103,1) |

3,62 (92,0) |

0,25 (6,4) |

0,19 (4,8) |

| 2½” | 4,12 (104,6) |

4,19 (106,4) |

3,75 (95,2) |

3,81 (96,8) |

3,38 (85,8) |

3,31 (84,1) |

4,56 (115,8) |

4,12 (104,6) |

0,25 (6,4) |

0,19 (4,8) |

| 3″ | 5,00 (127,0) |

5,06 (128,5) |

4,62 (117,5) |

4,69 (119,1) |

4,25 (108,0) |

4,19 (106,4) |

5,44 (138,2) |

5,00 (127,0) |

0,25 (6,4) |

0,19 (4,8) |

| 4″ | 6,19 (157,2) |

6,25 (158,8) |

5,69 (144,5) |

5,75 (146,1) |

5,19 (131,8) |

5,12 (130,0) |

6,62 (168,1) |

6,19 (157,2) |

0,25 (6,4) |

0,19 (4,8) |

| 5″ | 7,31 (185,7) |

7,38 (187,5) |

6,81 (173,0) |

6,88 (174,8) |

6,31 (160,3) |

6,25 (158,8) |

7,75 (196,9) |

7,31 (185,7) |

0,25 (6,4) |

0,19 (4,8) |

| 6″ | 8,50 (215,9) |

8,56 (217,5) |

8,00 (203,2) |

8,06 (204,7) |

7,50 (190,5) |

7,44 (189,0) |

8,94 (227,0) |

8,50 (215,9) |

0,25 (6,4) |

0,19 (4,8) |

| 8″ | 10,62 (269,8) |

10,69 (271,5) |

10,00 (254,0) |

10,06 (255,5) |

9,38 (238,3) |

9,31 (236,5) |

11,06 (281,0) |

10,62 (269,8) |

0,25 (6,4) |

0,19 (4,8) |

| 10″ | 12,75 (323,5) |

12,81 (325,4) |

12,00 (304,8) |

12,06 (306,3) |

11,25 (285,8) |

11,19 (284,2) |

13,19 (335,0) |

12,75 (323,5) |

0,25 (6,4) |

0,19 (4,8) |

| 12″ | 15,00 (381,0) |

15,06 (382,5) |

14,25 (362,0) |

14,31 (363,5) |

13,50 (342,9) |

13,44 (341,4) |

15,44 (392,2) |

15,00 (381,0) |

0,25 (6,4) |

0,19 (4,8) |

| 14″ | 16,25 (412,8) |

16,31 (414,3) |

15,50 (393,7) |

15,56 (395,2) |

14,75 (374,7) |

14,69 (373,1) |

16,69 (423,9) |

16,25 (412,8) |

0,25 (6,4) |

0,19 (4,8) |

| 16″ | 18,50 (469,9) |

18,56 (471,5) |

17,62 (447,6) |

17,69 (449,3) |

16,75 (425,5) |

16,69 (423,9) |

18,94 (481,0) |

18,50 (469,9) |

0,25 (6,4) |

0,19 (4,8) |

| 18″ | 21,00 (533,4) |

21,06 (535,0) |

20,12 (511,0) |

20,19 (512,8) |

19,25 (489,0) |

19,19 (487,4) |

21,44 (544,6) |

21,00 (533,4) |

0,25 (6,4) |

0,19 (4,8) |

| 20″ | 23,00 (584,2) |

23,06 (585,8) |

22,00 (558,8) |

22,06 (560,3) |

21,00 (533,4) |

20,94 (531,9) |

23,44 (595,4) |

23,00 (584,2) |

0,25 (6,4) |

0,19 (4,8) |

| 24″ | 27,25 (692,2) |

27,31 (693,7) |

26,25 (666,8) |

26,31 (668,3) |

25,25 (641,4) |

25,19 (639,8) |

27,69 (703,3) |

27,25 (692,2) |

0,25 (6,4) |

0,19 (4,8) |

ANSI B16.5 Class 150# Large Tongue & Groove Flanges Dimensions

|

Nominal |

Large Tongue |

Large Tongue |

Gasket |

Number |

Size of |

Bolt Torque |

Comp Force |

Max. Gasket |

Internal |

Min. Rec’d |

Min. Rec’d |

Max. Rec’d/Avail. |

Preferred |

|

Pipe Size |

Contact I.D. |

Contact O.D. |

Contact Area |

Of |

Bolts |

at 60ksi Stress |

Per Bolt @ 60ksi |

Stress Avail. |

Pressure |

Gasket Stress |

Torque/Bolt |

Gasket Stress |

Torque/Bolt |

|

(in) |

(in) |

(in) |

(sq.in.) |

Bolts |

(in) |

(ft.lbs.) |

(psi) |

(psi) |

(psig) |

(psi) |

(ft.lbs.) |

(psi) |

(ft.lbs.) |

|

0.5 |

1.00 |

1.38 |

0.71 |

4 |

0.50 |

60 |

7560 |

42594 |

<300 |

4800 |

7 |

10000 |

14 |

|

0.75 |

1.31 |

1.69 |

0.89 |

4 |

0.50 |

60 |

7560 |

33791 |

<300 |

4800 |

9 |

10000 |

18 |

|

1 |

1.50 |

2.00 |

1.37 |

4 |

0.50 |

60 |

7560 |

22013 |

<300 |

4800 |

13 |

10000 |

27 |

|

1.25 |

1.88 |

2.50 |

2.13 |

4 |

0.50 |

60 |

7560 |

14186 |

<300 |

4800 |

20 |

10000 |

42 |

|

1.5 |

2.12 |

2.88 |

2.98 |

4 |

0.50 |

60 |

7560 |

10137 |

<300 |

4800 |

28 |

10000 |

59 |

|

2 |

2.88 |

3.62 |

3.78 |

4 |

0.63 |

120 |

12120 |

12839 |

<300 |

4800 |

45 |

10000 |

93 |

|

2.5 |

3.38 |

4.12 |

4.36 |

4 |

0.63 |

120 |

12120 |

11128 |

<300 |

4800 |

52 |

10000 |

108 |

|

3 |

4.25 |

5.00 |

5.45 |

4 |

0.63 |

120 |

12120 |

8902 |

<300 |

4800 |

65 |

8902 |

120 |

|

3.5 |

4.75 |

5.50 |

6.03 |

8 |

0.63 |

120 |

12120 |

16067 |

<300 |

4800 |

36 |

10000 |

75 |

|

4 |

5.19 |

6.19 |

8.93 |

8 |

0.63 |

120 |

12120 |

10854 |

<300 |

4800 |

53 |

10854 |

120 |

|

5 |

6.31 |

7.31 |

10.69 |

8 |

0.75 |

200 |

18120 |

13558 |

<300 |

4800 |

71 |

13558 |

200 |

|

6 |

7.50 |

8.50 |

12.56 |

8 |

0.75 |

200 |

18120 |

11541 |

<300 |

4800 |

83 |

11541 |

200 |

|

8 |

9.38 |

10.62 |

19.47 |

8 |

0.75 |

200 |

18120 |

7446 |

<300 |

4800 |

129 |

7446 |

200 |

|

10 |

11.25 |

12.75 |

28.26 |

12 |

0.88 |

320 |

25140 |

10675 |

<300 |

4800 |

144 |

10675 |

320 |

|

12 |

13.50 |

15.00 |

33.56 |

12 |

0.88 |

320 |

25140 |

8990 |

<300 |

4800 |

171 |

8990 |

320 |

|

14 |

14.75 |

16.25 |

36.50 |

12 |

1.00 |

490 |

33060 |

10868 |

<300 |

4800 |

216 |

10868 |

490 |

|

16 |

16.75 |

18.50 |

48.42 |

16 |

1.00 |

490 |

33060 |

10923 |

<300 |

4800 |

215 |

10923 |

490 |

|

18 |

19.25 |

21.00 |

55.29 |

16 |

1.13 |

710 |

43680 |

12639 |

<300 |

4800 |

270 |

12639 |

710 |

|

20 |

21.00 |

23.00 |

69.08 |

20 |

1.13 |

710 |

43680 |

12646 |

<300 |

4800 |

269 |

12646 |

710 |

|

24 |

25.25 |

27.25 |

82.43 |

20 |

1.25 |

1000 |

55740 |

13525 |

<300 |

4800 |

355 |

13525 |

1000 |

ANSI B16.5 Class 300# Large Tongue & Groove Flanges Dimensions

|

Nominal |

Large Tongue |

Large Tongue |

Gasket |

Number |

Size of |

Bolt Torque |

Comp Force |

Max. Gasket |

Internal |

Min. Rec’d |

Min. Rec’d |

Max. Rec’d/Avail. |

Preferred |

|

Pipe Size |

Contact I.D. |

Contact O.D. |

Contact Area |

Of |

Bolts |

at 60ksi Stress |

Per Bolt @ 60ksi |

Stress Avail. |

Pressure |

Gasket Stress |

Torque/Bolt |

Gasket Stress |

Torque/Bolt |

|

(in) |

(in) |

(in) |

(sq.in.) |

Bolts |

(in) |

(ft.lbs.) |

(psi) |

(psi) |

(psig) |

(psi) |

(ft.lbs.) |

(psi) |

(ft.lbs.) |

|

0.5 |

1.00 |

1.38 |

0.71 |

4 |

0.50 |

60 |

7560 |

42594 |

<800 |

6200 |

12 |

10000 |

14 |

|

0.75 |

1.31 |

1.69 |

0.89 |

4 |

0.63 |

120 |

12120 |

54174 |

<800 |

6200 |

21 |

10000 |

22 |

|

1 |

1.50 |

2.00 |

1.37 |

4 |

0.63 |

120 |

12120 |

35290 |

<800 |

6400 |

28 |

10000 |

34 |

|

1.25 |

1.88 |

2.50 |

2.13 |

4 |

0.63 |

120 |

12120 |

22742 |

<800 |

6400 |

43 |

10000 |

53 |

|

1.5 |

2.12 |

2.88 |

2.98 |

4 |

0.75 |

200 |

18120 |

24298 |

<800 |

6400 |

64 |

10000 |

82 |

|

2 |

2.88 |

3.62 |

3.78 |

8 |

0.63 |

120 |

12120 |

25679 |

<800 |

6400 |

46 |

10000 |

47 |

|

2.5 |

3.38 |

4.12 |

4.36 |

8 |

0.75 |

200 |

18120 |

33273 |

<800 |

6400 |

60 |

10000 |

60 |

|

3 |

4.25 |

5.00 |

5.45 |

8 |

0.75 |

200 |

18120 |

26618 |

<800 |

6400 |

88 |

10000 |

75 |

|

3.5 |

4.75 |

5.50 |

6.03 |

8 |

0.75 |

200 |

18120 |

24021 |

<800 |

6400 |

99 |

10000 |

83 |

|

4 |

5.19 |

6.19 |

8.93 |

8 |

0.75 |

200 |

18120 |

16227 |

<800 |

6400 |

125 |

10000 |

123 |

|

5 |

6.31 |

7.31 |

10.69 |

8 |

0.75 |

200 |

18120 |

13558 |

<800 |

6400 |

156 |

10000 |

148 |

|

6 |

7.50 |

8.50 |

12.56 |

12 |

0.75 |

200 |

18120 |

17312 |

<800 |

6400 |

131 |

10000 |

116 |

|

8 |

9.38 |

10.62 |

19.47 |

12 |

0.88 |

320 |

25140 |

15496 |

<800 |

6400 |

205 |

10000 |

207 |

|

10 |

11.25 |

12.75 |

28.26 |

16 |

1.00 |

490 |

33060 |

18718 |

<800 |

6400 |

219 |

10000 |

262 |

|

12 |

13.50 |

15.00 |

33.56 |

16 |

1.13 |

710 |

43680 |

20826 |

<800 |

6400 |

319 |

15000 |

511 |

|

14 |

14.75 |

16.25 |

36.50 |

20 |

1.13 |

710 |

43680 |

23933 |

<800 |

6600 |

287 |

15000 |

445 |

|

16 |

16.75 |

18.50 |

48.42 |

20 |

1.25 |

1000 |

55740 |

23021 |

<800 |

6600 |

401 |

15000 |

652 |

|

18 |

19.25 |

21.00 |

55.29 |

24 |

1.25 |

1000 |

55740 |

24194 |

<800 |

6400 |

439 |

15000 |

620 |

|

20 |

21.00 |

23.00 |

69.08 |

24 |

1.25 |

1000 |

55740 |

19365 |

<800 |

6400 |

484 |

15000 |

775 |

|

24 |

25.25 |

27.25 |

82.43 |

24 |

1.50 |

1600 |

84300 |

24546 |

<800 |

6400 |

662 |

15000 |

978 |

|

Application

Tongue & Groove Flanges Application

ASME B16.5 Groove and Tongue Flanges are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of Tongue & Groove Flanges through a network of stock-keeping branches. These Tongue & Groove Flange is use in various industrial applications like :

- Tongue & Groove Flanges uses in Chemical Industry

- Large Tongue & Groove Flanges uses in Plumbing

- ANSI B16.5 Tongue & Groove Flanges uses in Power Plant

- Tongue & Groove Flange uses in Food Processing Industry

- Small Groove & Tongue Flanges uses in Structural Pipe

- Stainless Steel Tongue & Groove Flanges uses in Oil and Gas Pipeline

- Tongue & Groove Flanges uses in Heating

- Tongue & Groove Pipe Flanges uses in Water Supply Systems

- Tongue & Groove Flanges uses in Paper & Pulp Industry

- Groove & Tongue Flange uses in General Purpose Applications

- Steel Tongue & Groove Flanges uses in Fabrication Industry

|

Related products

ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706